We Made the Perfect CPU Cooler | Intel vs. AMD Curvature & Coldplate Engineering

Last Updated:

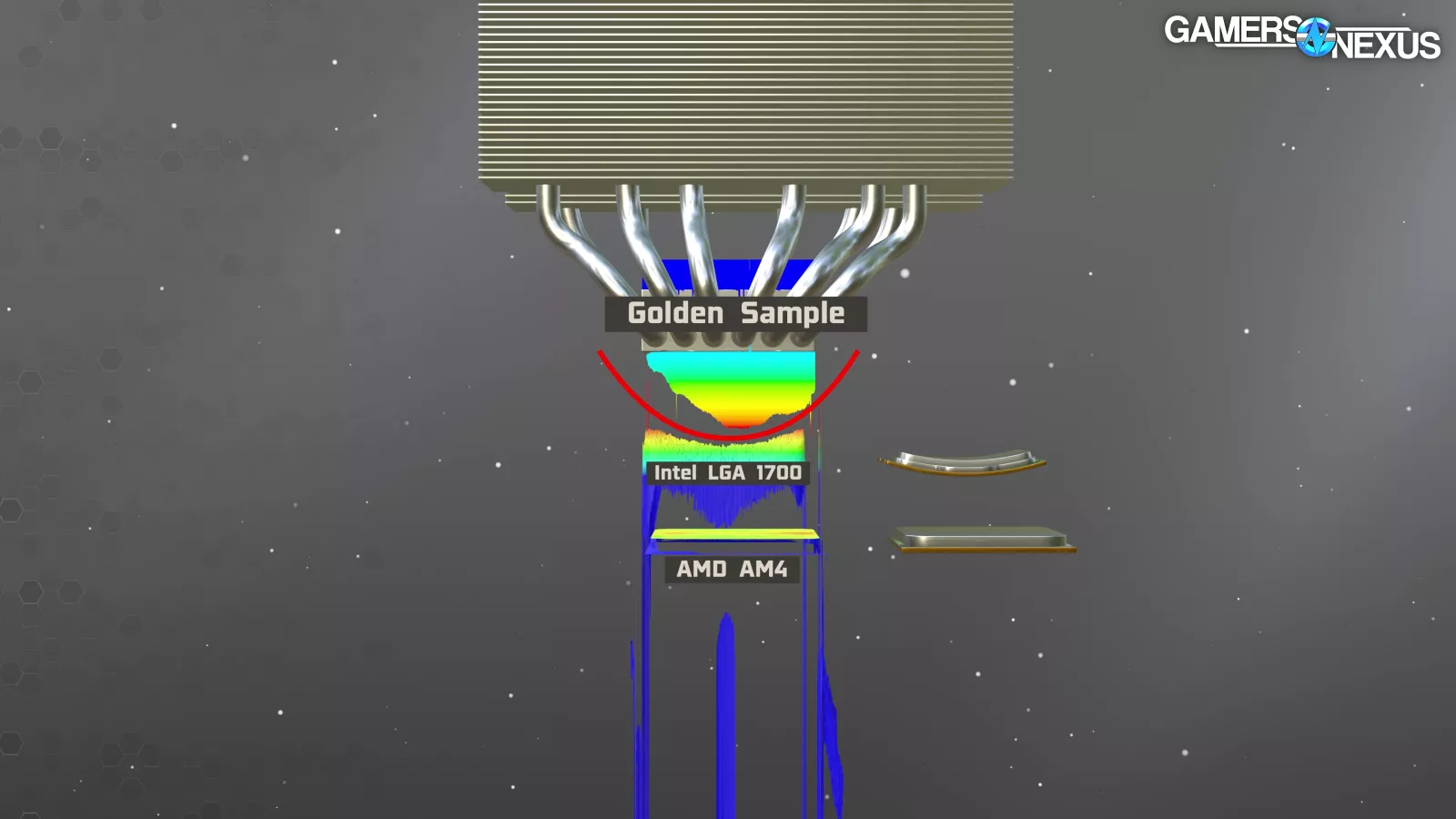

We worked with Scythe to create a “golden sample” CPU cooler

The Highlights

- We had a CPU cooler’s coldplate custom manufactured to match the curvature of an Intel heat spreader

- We also tested a flatter coldplate to match AM4’s flatter CPUs but that didn’t do as well as we expected

- Our golden sample was designed for LGA1700 but also did surprisingly well on AM4

Table of Contents

- AutoTOC

Intro

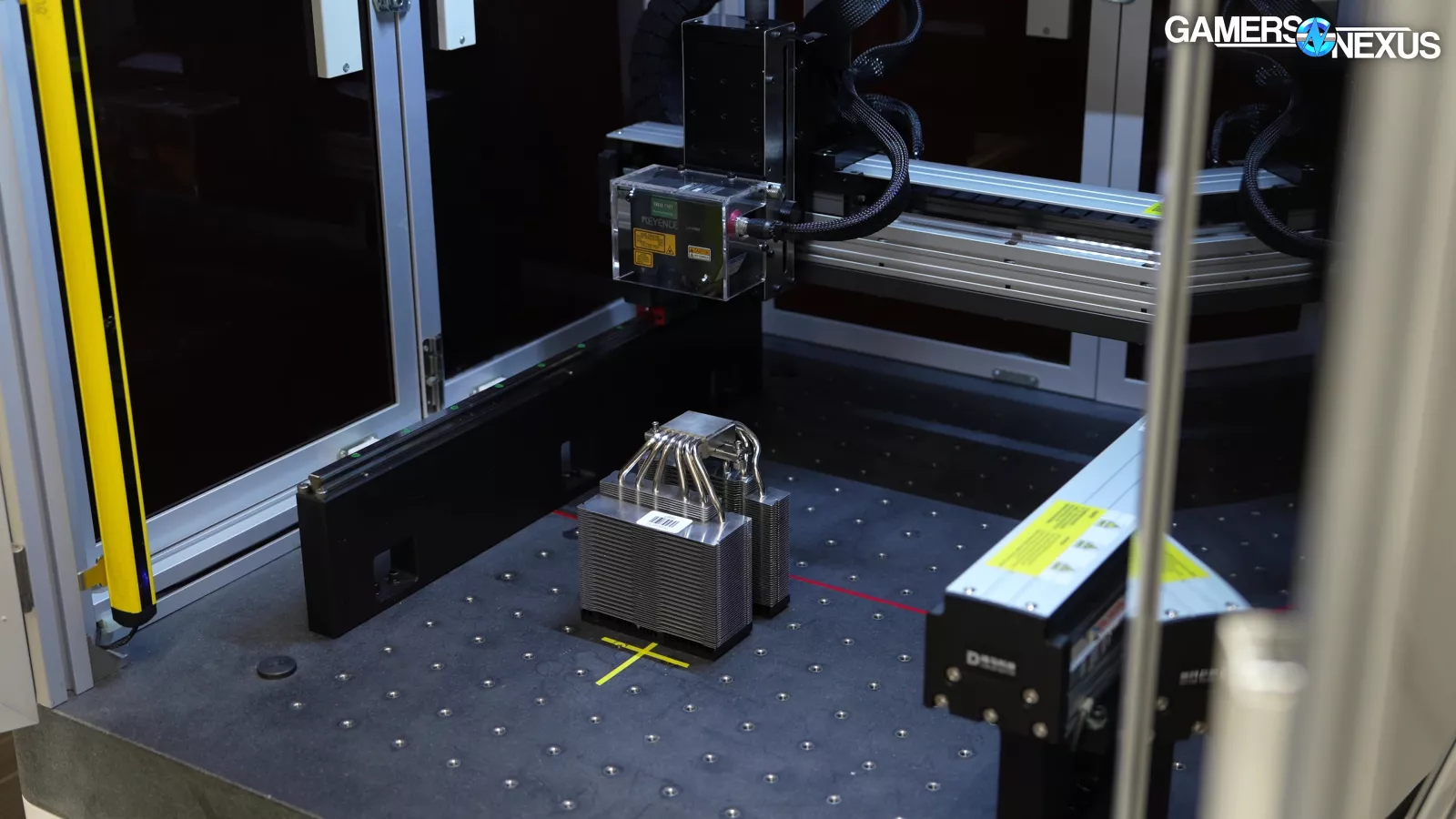

We’re using our $60,000 laser scanner to create a 3D map of CPU heat spreaders and CPU cooler with microscopic accuracy. We also had CPU cooler coldplates custom manufactured to match the curvature of the heat spreader when under clamping pressure from Intel’s ILM, which theoretically makes for a perfect match with the CPU IHS. The plan was to create a “golden sample” cooler for a specific CPU.

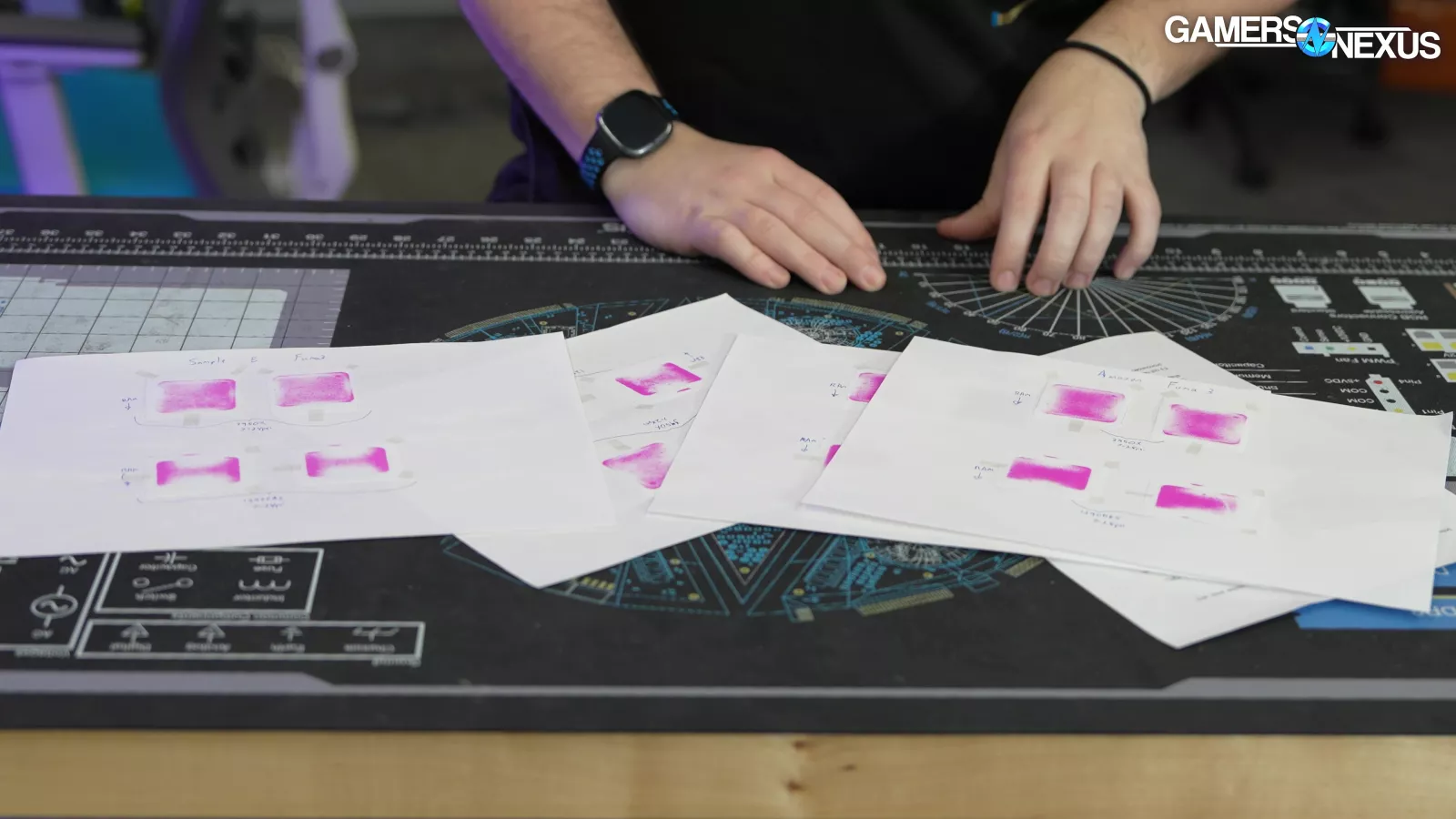

Next, we used chemically reactive pressure paper and a calibrated scanner to test for contact between the different coldplates and IHS, then created a pseudocolor map of the pressure distribution.

Editor's note: This was originally published on May 5, 2024 as a video. This content has been adapted to written format for this article and is unchanged from the original publication.

Credits

Testing, Host, Writing, Editing

Steve Burke

Testing

Patrick Lathan

Mike Gaglione

Camera, Video Editing

Vitalii Makhnovets

3D Animation, Editing

Andrew Coleman

Writing, Web Editing

Jimmy Thang

And all of that brings us to our thermal testing, where we’ll finally get around to evaluating a long-running weak point in cooler reviews. When a cooler review only considers one IHS style, it’s possible that the cooler performs better on the other. We’ve been open about this weakness for years but made the decision to go with one platform since a proper review takes so much time. But a few months ago, we added Intel to our cooler test suite to accommodate both styles. Now we get to show you why we did that.

This will be a fun science piece on the design of coolers, coldplates, and heat spreaders.

This is what makes cooler reviews complicated: In our laser scanner, you will see scans of cooler coldplates for the same model of CPU cooler -- except we had one of them custom manufactured.

Actually, these were custom-made by Scythe at our request for this testing. They didn’t sponsor this content, but shared a similar scientific curiosity. We wanted to test the same cooler in every single facet, except with only the cold plate changing to optimize for Intel or for AMD.

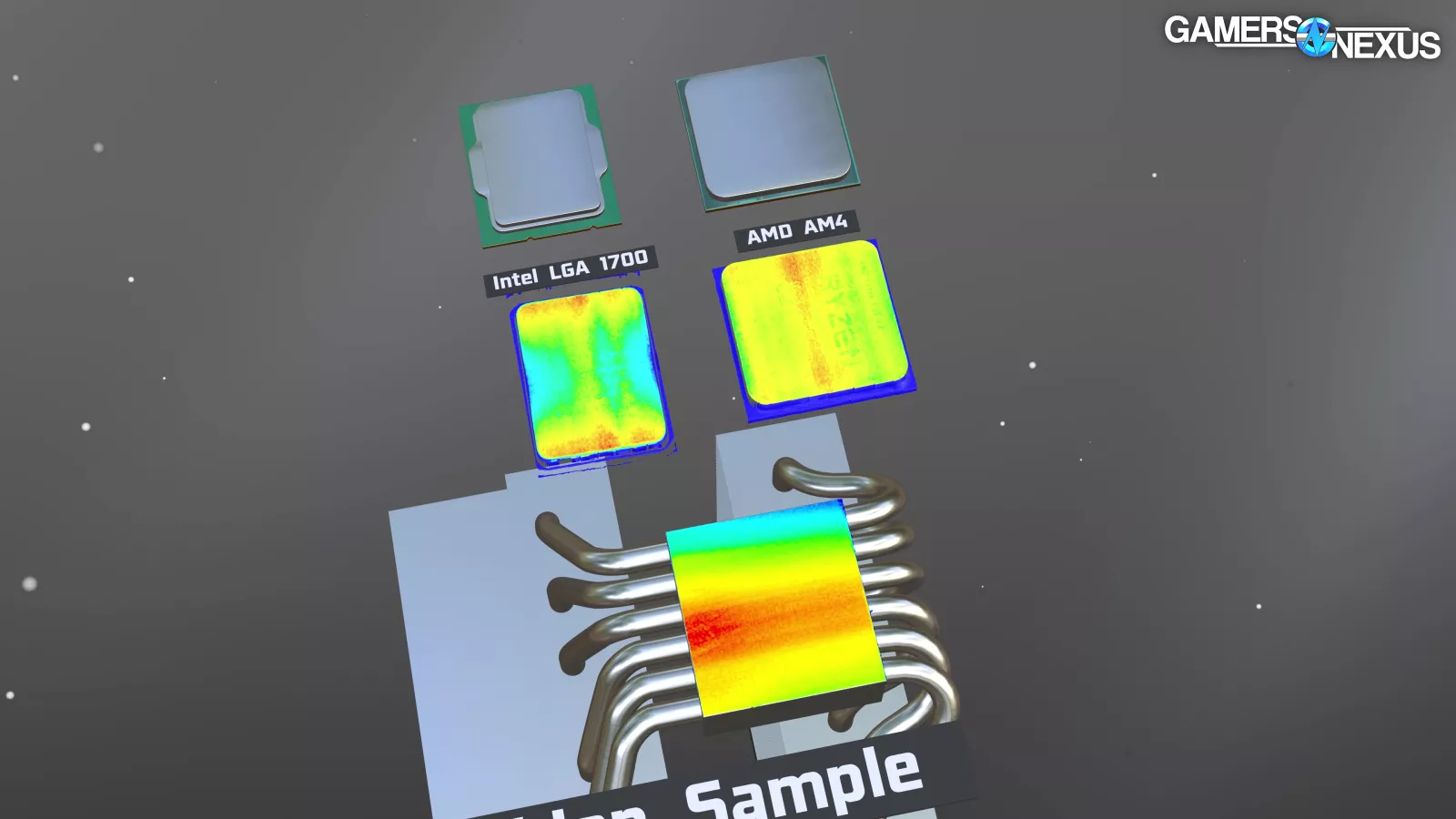

It’s not news that an IHS has a slight curvature, but we’ve always heard that Intel had a more pronounced curvature while AMD is flatter. We’re validating that common industry topic today. We asked Scythe to custom manufacture coolers that would best fit the theory, but we’ll see how it works in practice.

CPU Curvature

The CPU is a known and fixed quantity. The only external factor is the ILM, which applies uneven pressure that can slightly bend the IHS and CPU under load. Let’s start with the CPU.

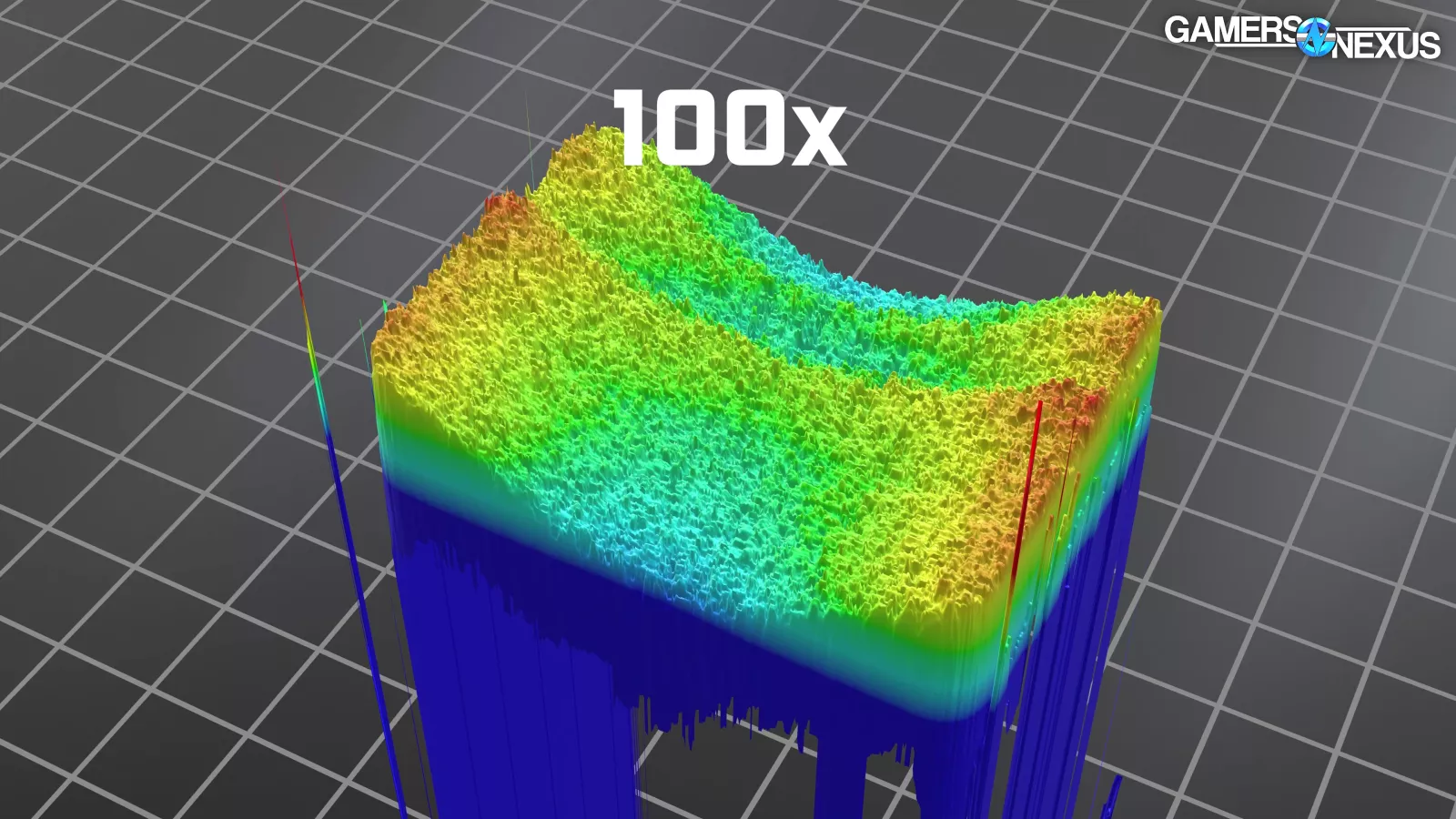

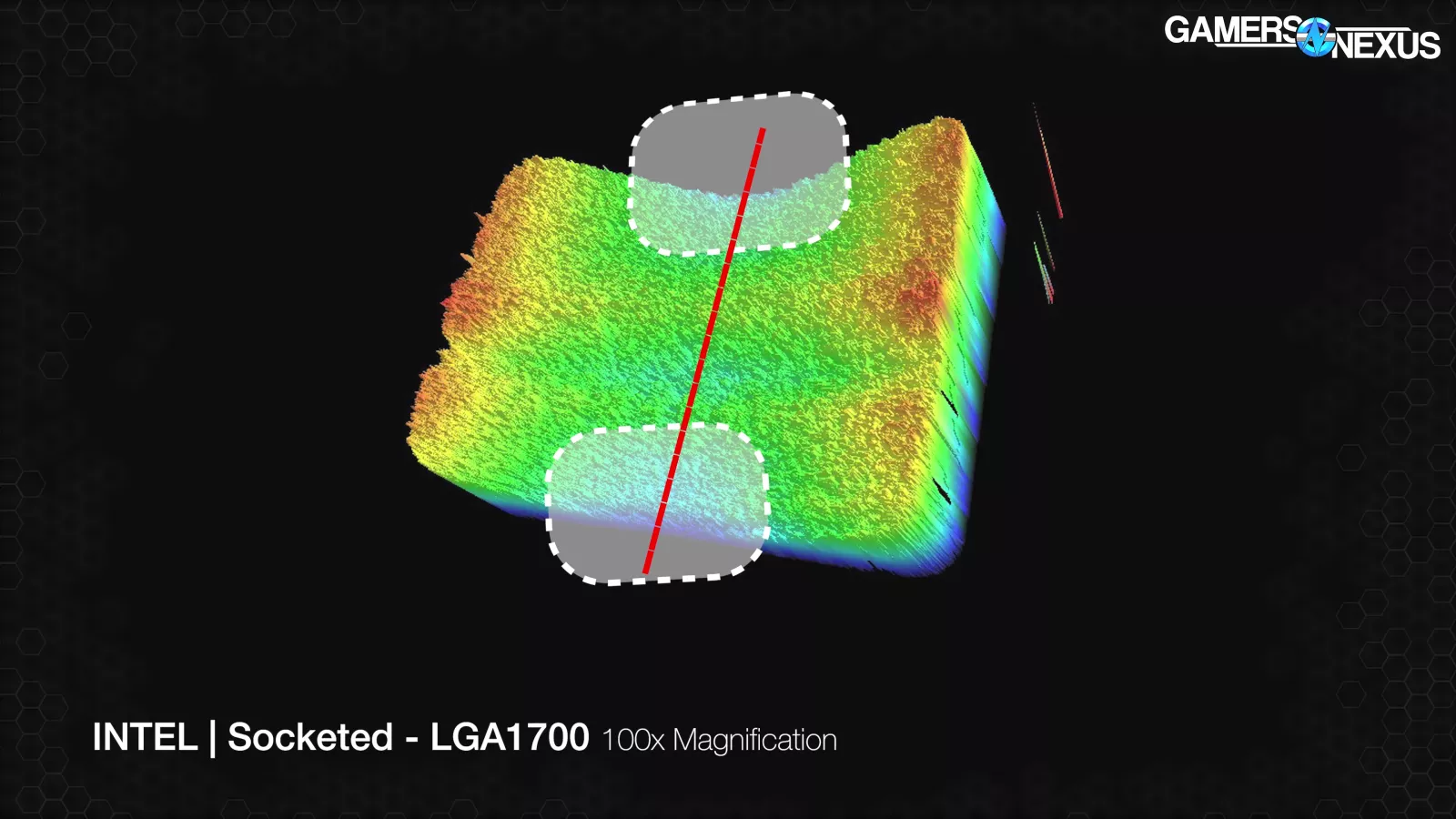

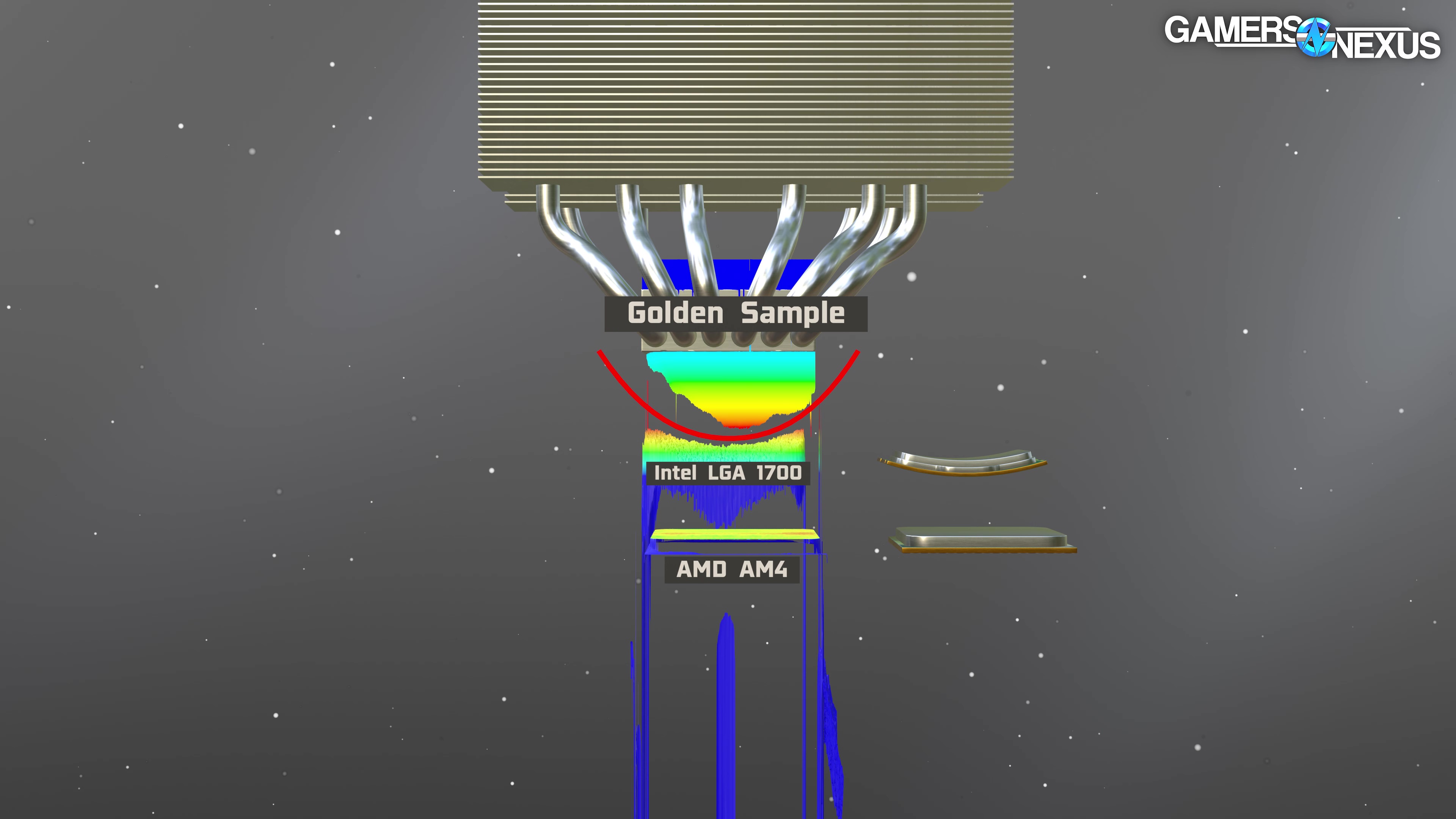

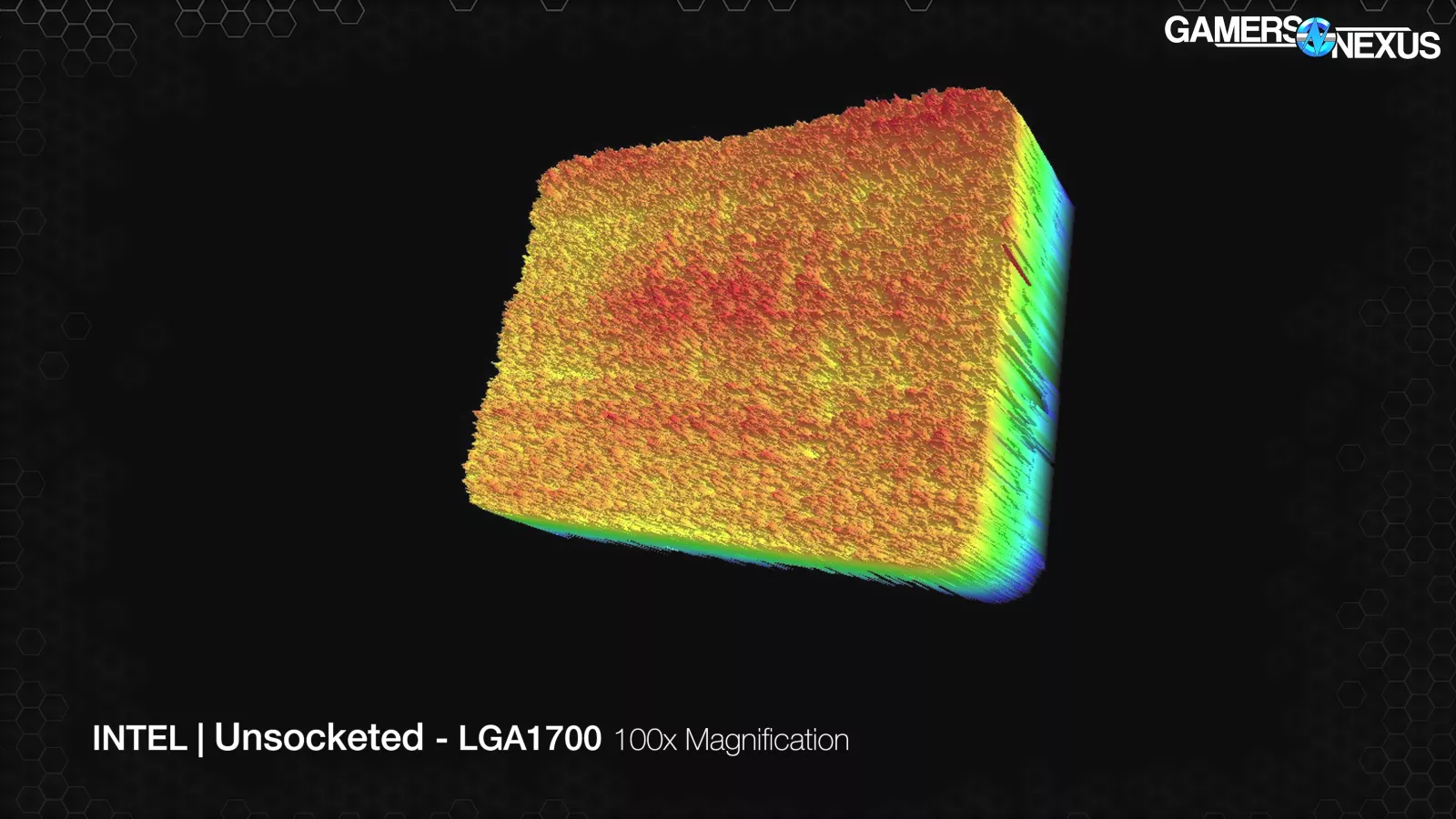

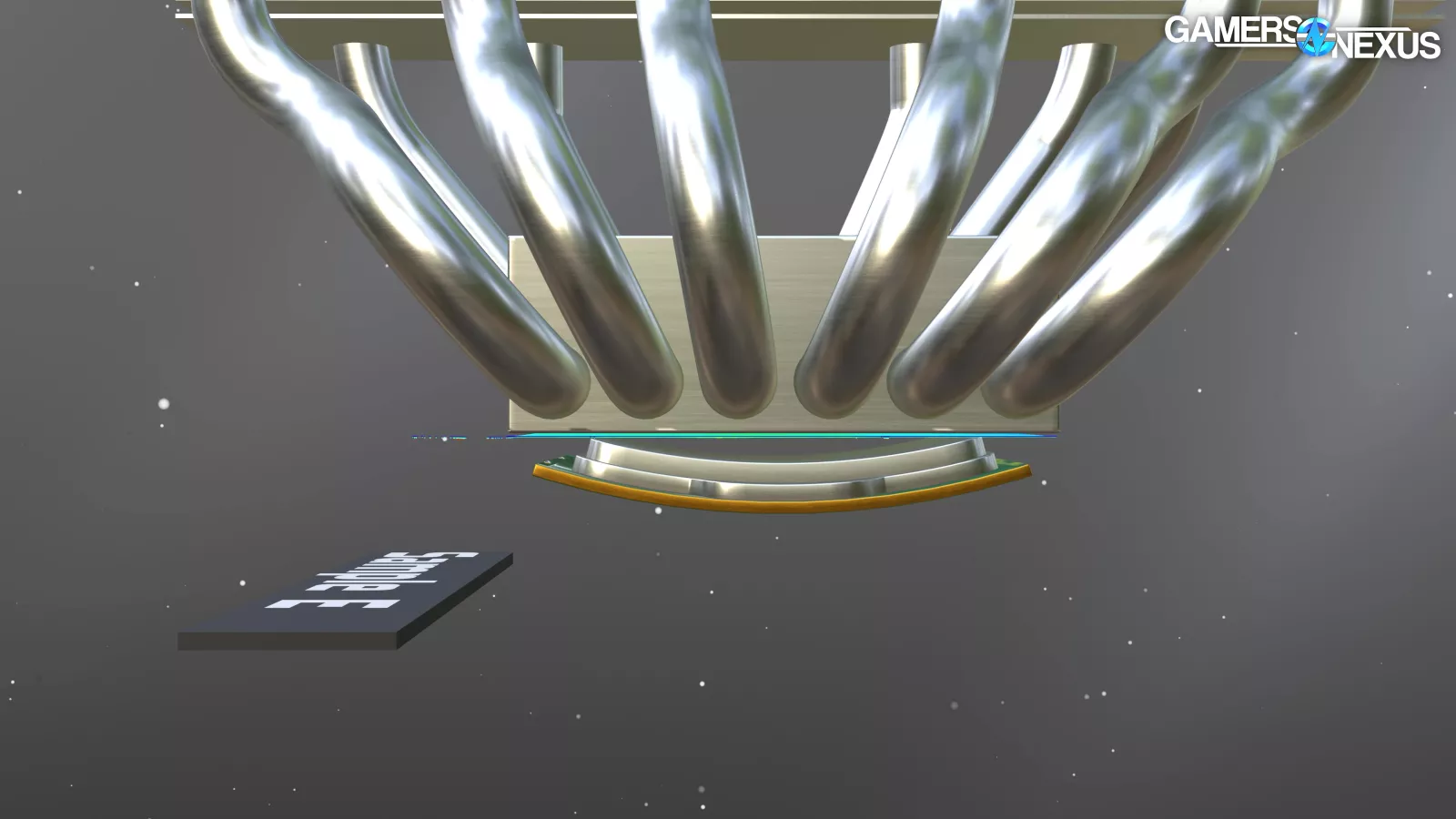

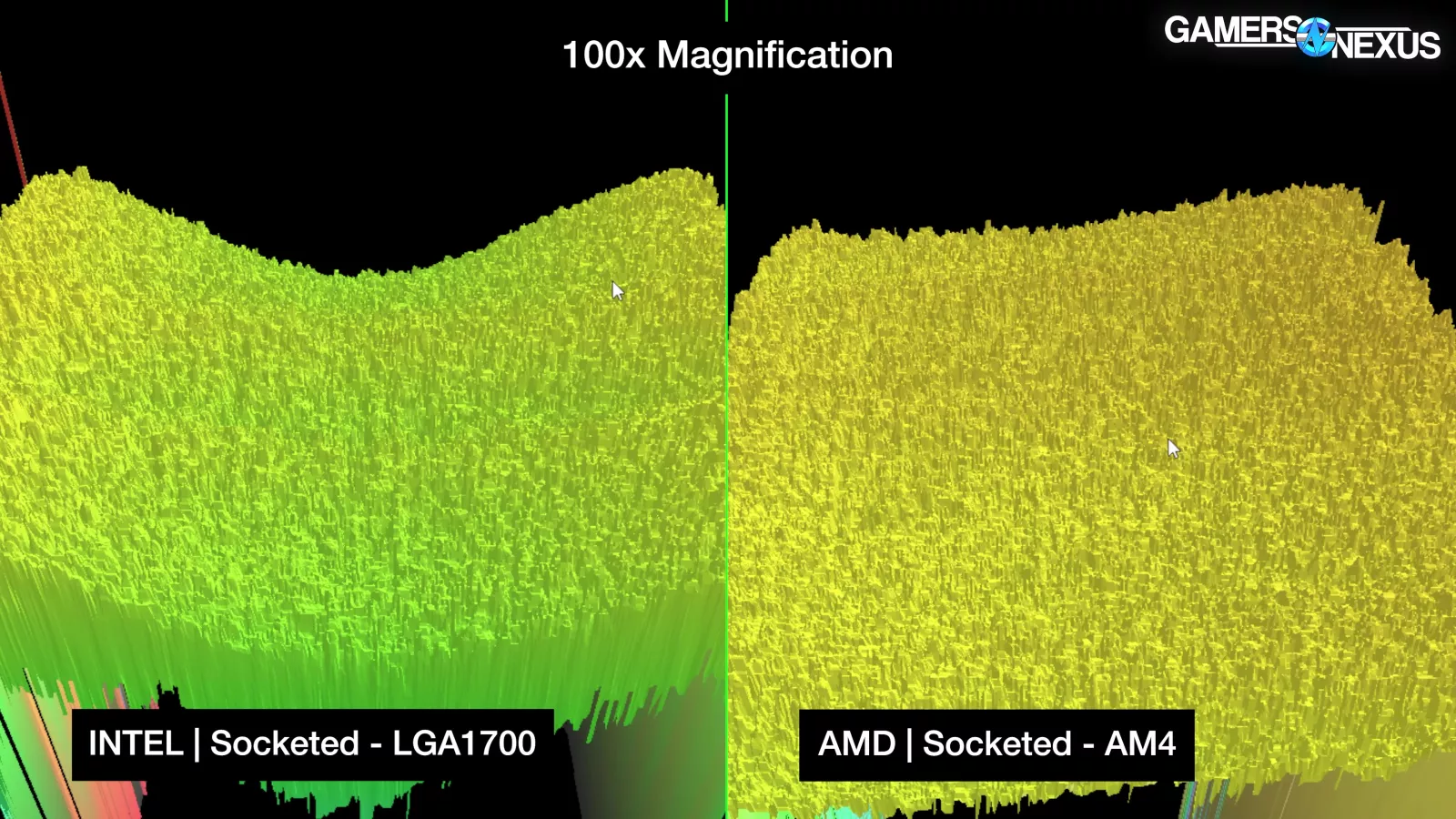

Here’s a modern Intel CPU with the ILM clamped-down and at a 100x magnification. You can see that at the points where the clamp applies the force, at the middle edges on the long side, the CPU is clearly pushed downward and deforms centrally. You can see that in our animation we made back when we reviewed the contact frames, which are known to flatten the CPU. We’ve already proven that they do in the past.

That indent will absolutely manifest itself in the form of contact with a cold plate. We’d ideally want a coldplate to mate with it perfectly.

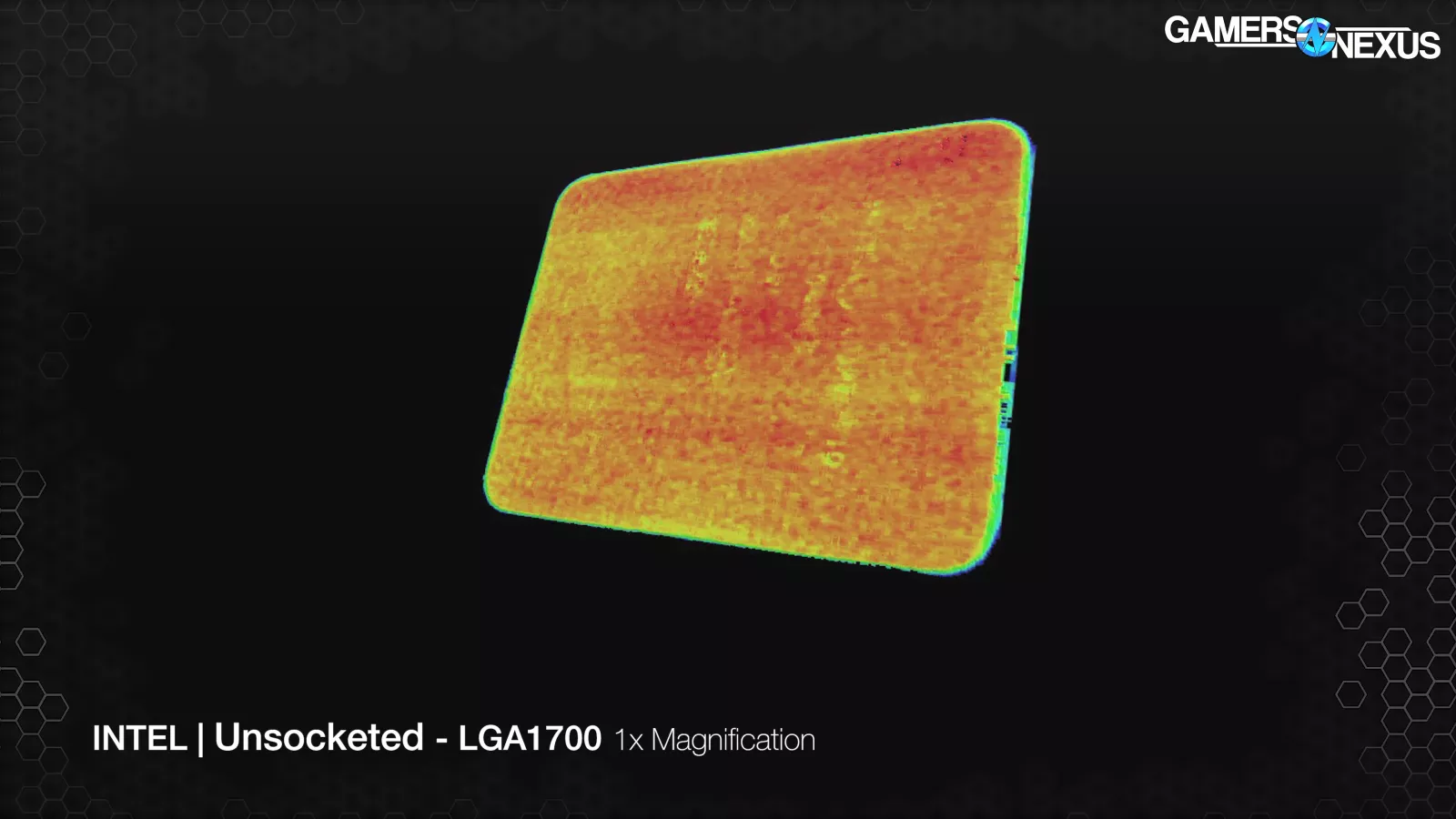

What’s interesting is that an unsocketed Intel CPU just sitting flat in the scanner is almost completely flat, even if it’s been mounted before.

This is magnified at 100x, and even still, we’re really only seeing the usual microscopic imperfections but very little curvature. This CPU has been used a lot too, so if it were to be permanently bent, we’d see it by now.

That clamp is definitely deforming it in ways for which the cold plate could be tuned.

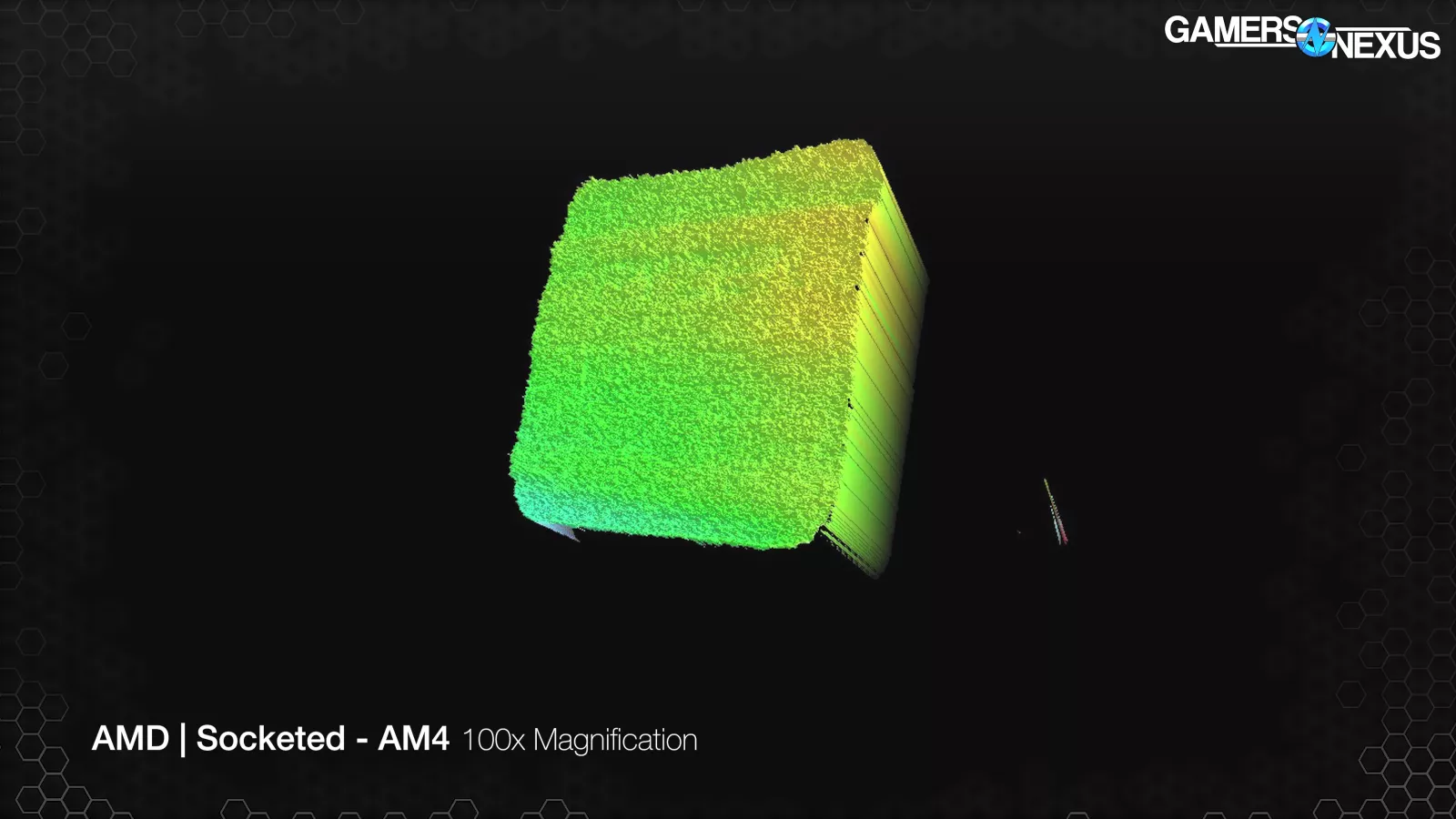

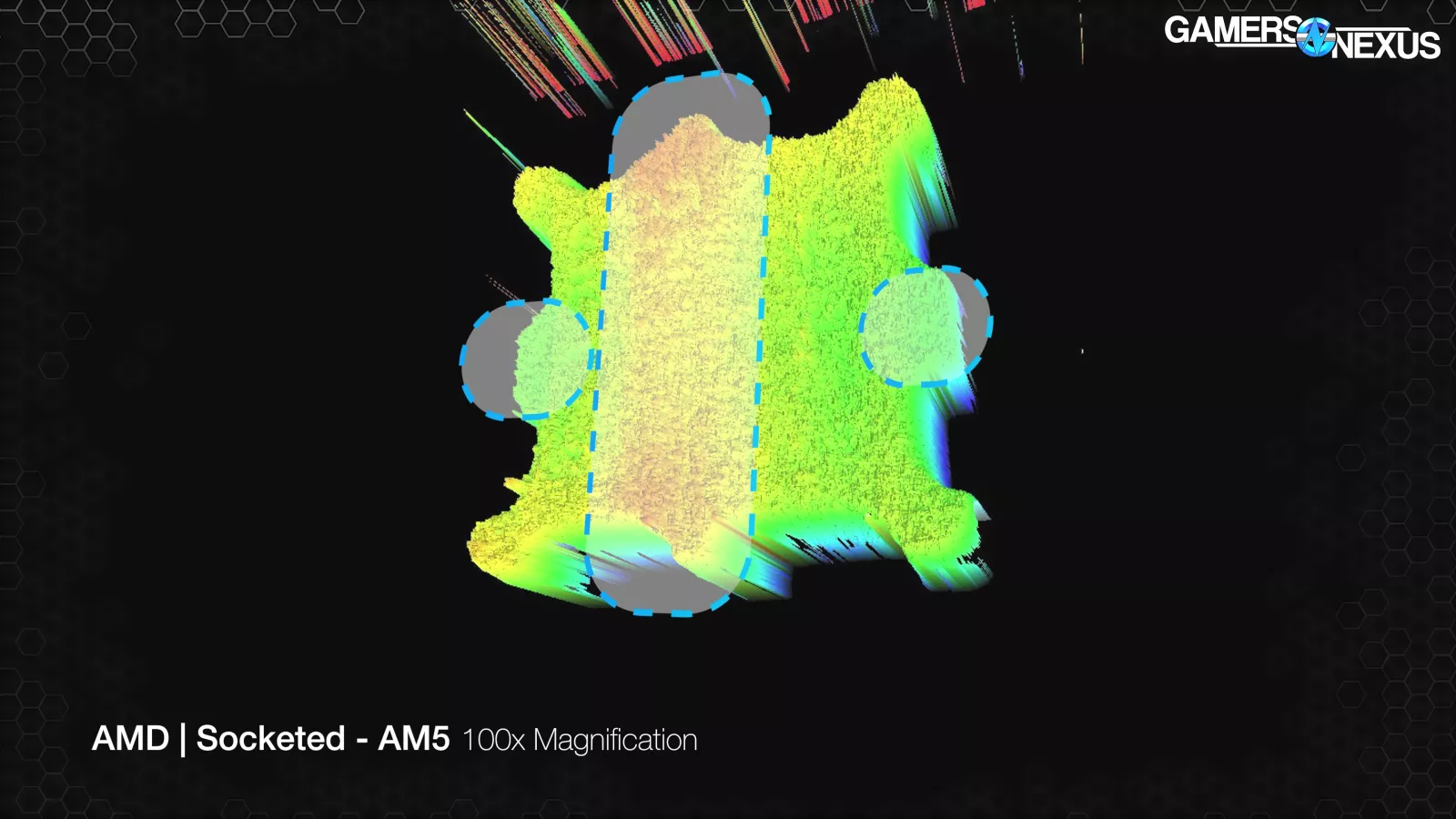

Here’s a look at an AM4 CPU. Even at 100x and clamped, the CPU is almost perfectly flat. The old PGA socket doesn’t change anything from flat, so we’re just showing this. There’s a slight ripple in the surface, but that’s a mix of the magnification and the imperfect process of leveling the device being scanned. You can consider this as functionally flat. That means Intel and AMD AM4 would have different cold plate curvature optimizations from a cooler manufacturer’s perspective.

AM5 has an ILM though, and that’s where this gets interesting.

AM5’s pattern is woefully opposite of Intel’s: You can see that it bows upward in the center, at the points perpendicular to the clamping direction. This is going to be problematic.

In terms of maximum cooler compatibility, this is actually the worst possible outcome. That means if a cooler tunes for Intel or AMD in a very precise way, it’ll be at possibly the worst intersection with the opposite IHS. Most coolers don’t fine-tune to this level, but the fact that the CPU indentations effectively intersect means the ideal setup would be CPU-specific.

But let’s try it.

Cooler Curvature

Based on our findings, to truly make a perfect cold plate, you’d need to make two versions of the same cooler. One would need a more curved cold plate, while the other would need a flatter one for AM4. If you wanted to accommodate AM5 optimally, you’d need 3 variations: The third would have to rotate the plate to align a concave plate with the convex AM5 IHS. For many boring reasons like economies of scale and customers getting confused and buying the wrong thing, most companies opt for a single solution that does its best to appeal to both IHS styles.

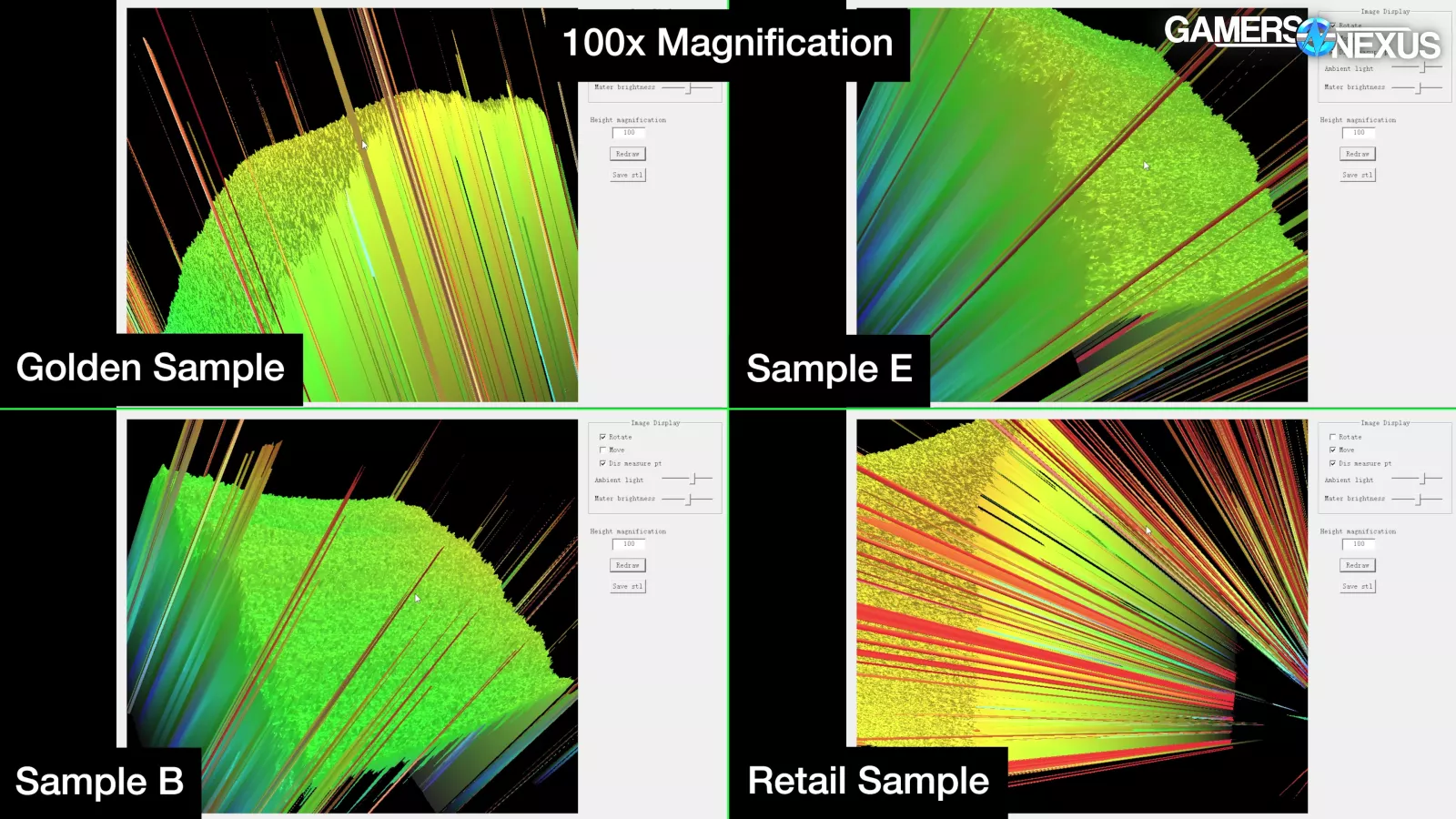

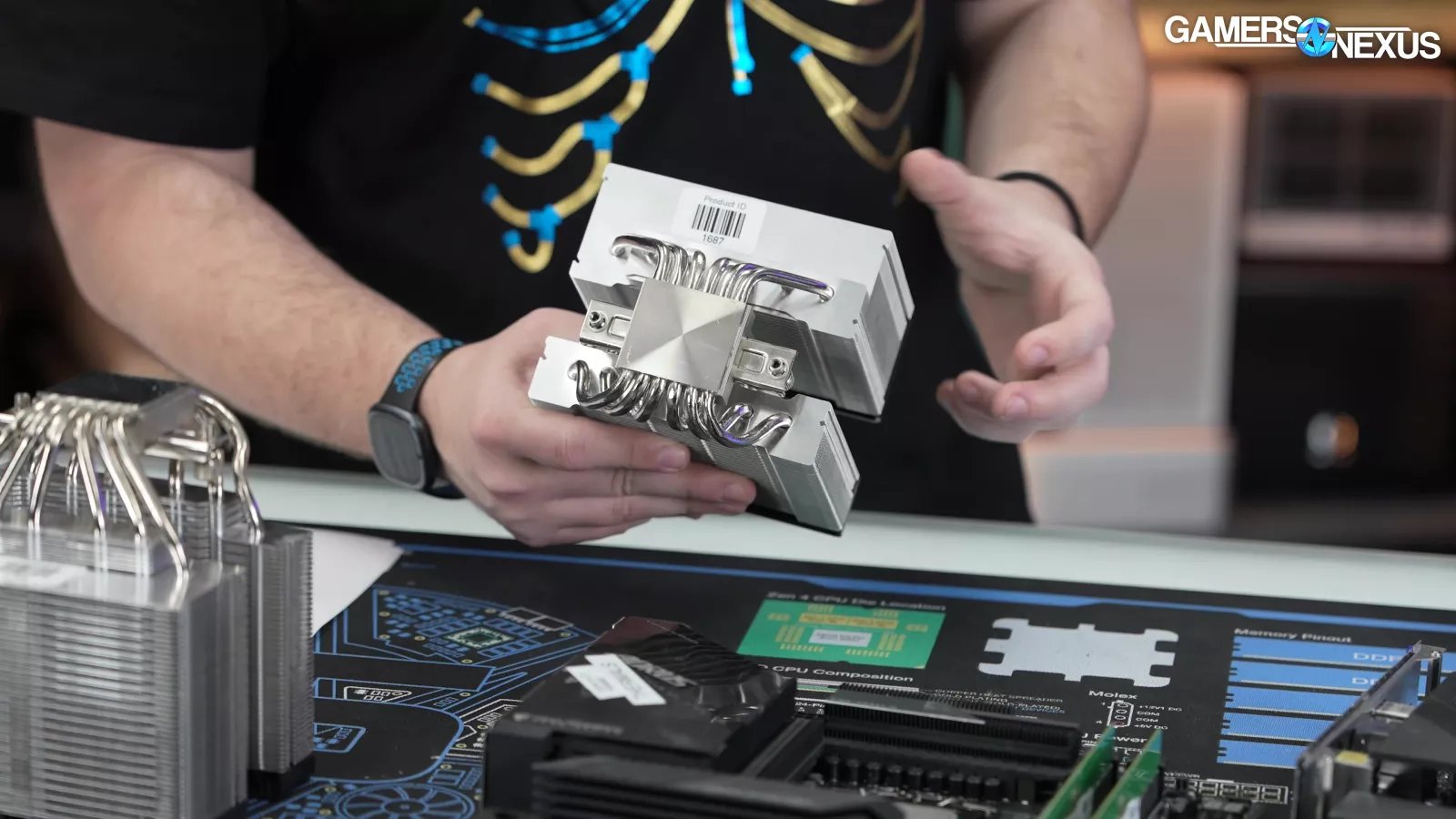

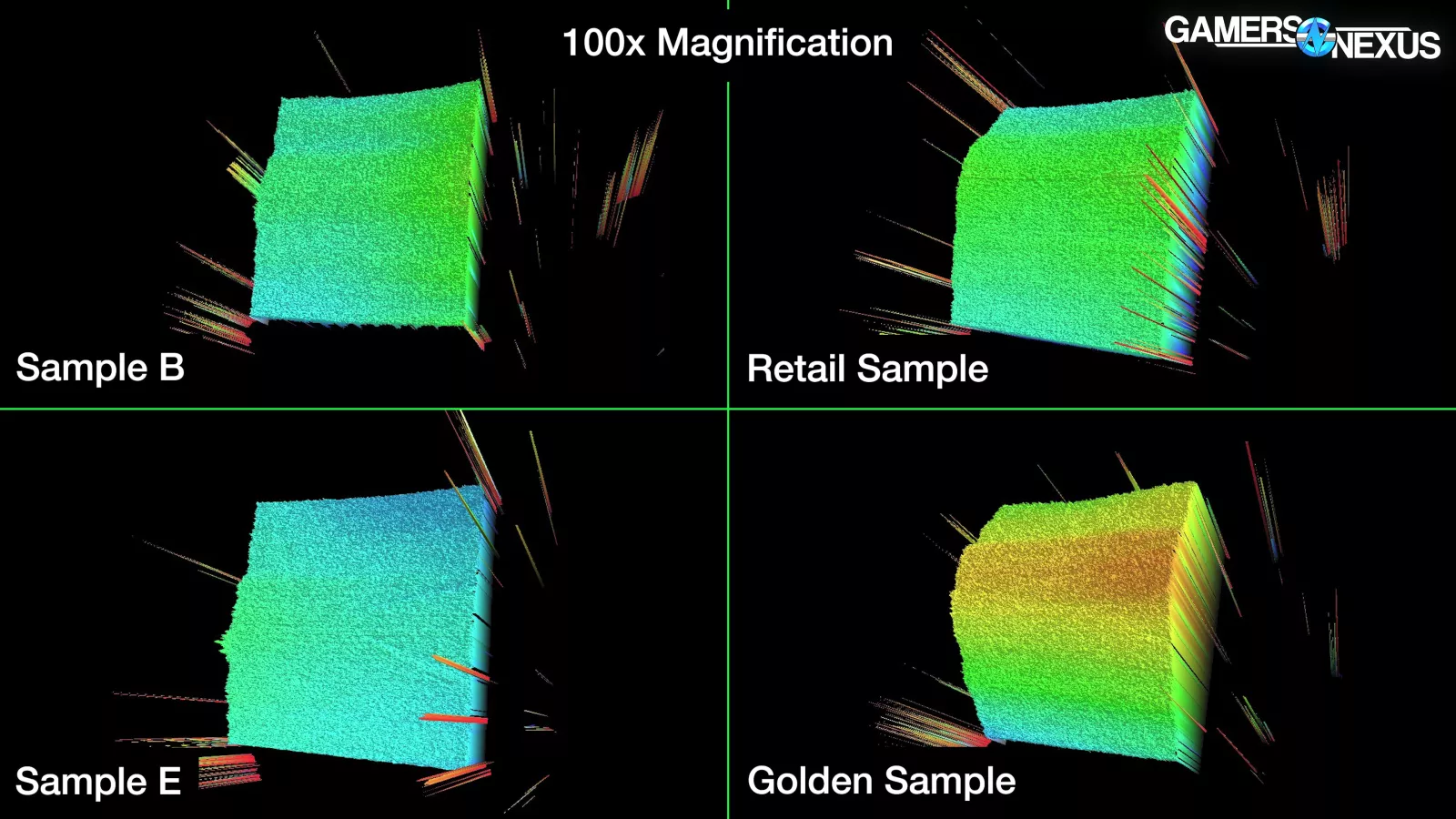

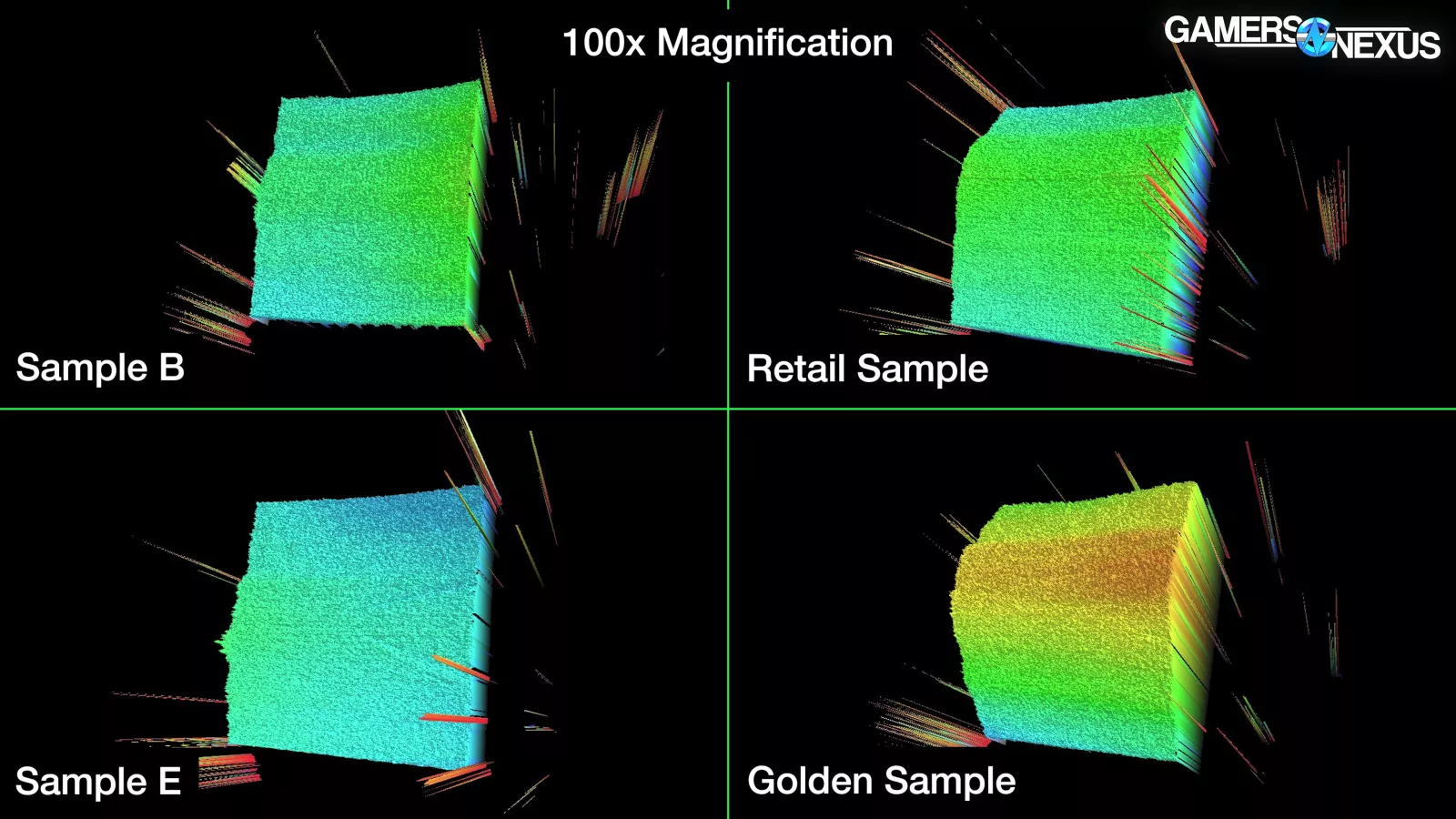

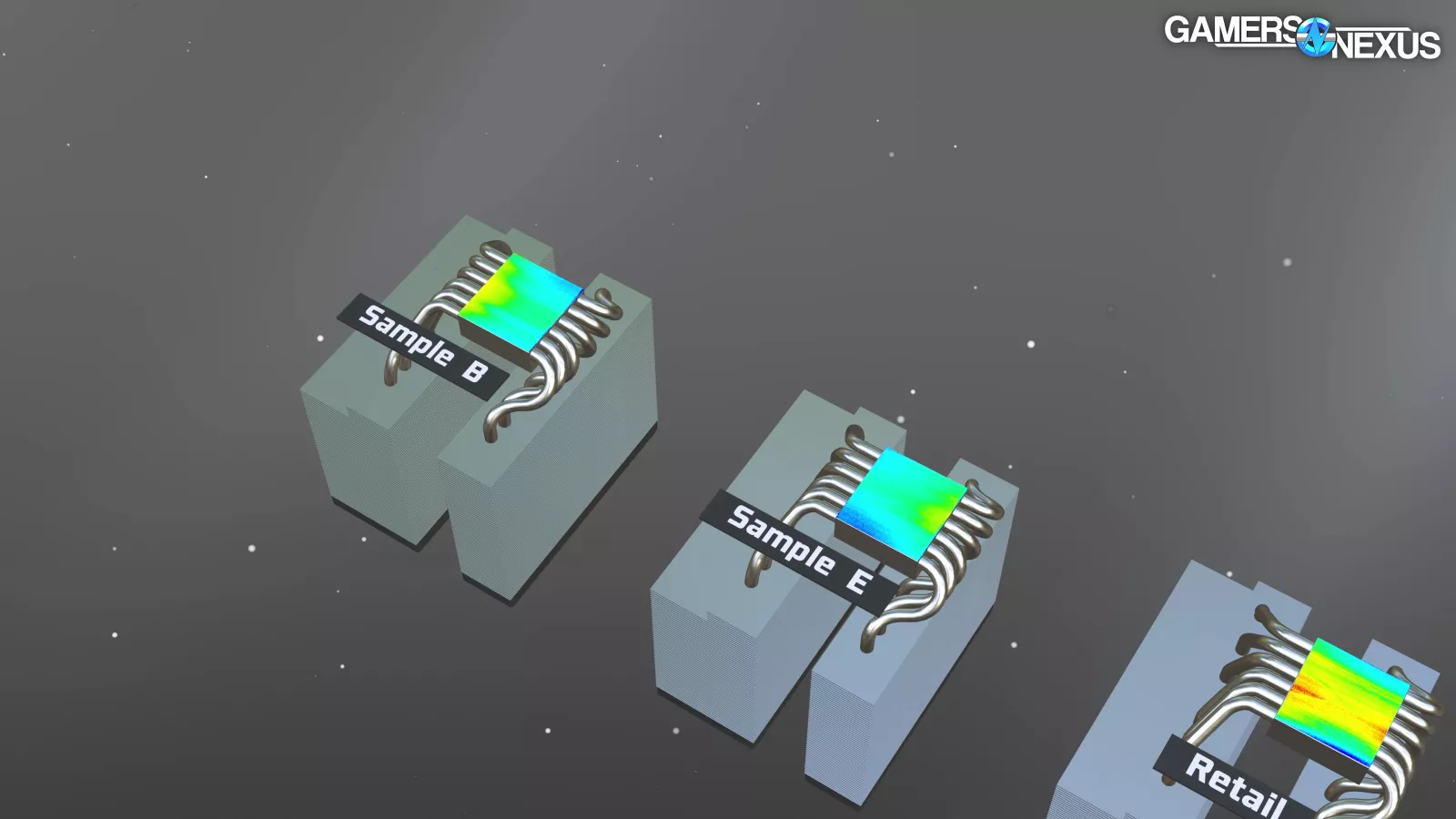

Here are our four coolers today:

All of these are the Scythe FUMA 3. One is a retail unit we bought from Amazon, the second is custom machined to have a flatter cold plate, the third was made with a more curved cold plate, and the fourth is a final retail-ready unit that Scythe hand-picked as being one of its best performers from the production line. Cooler variance, overall, is extremely low if you have good test processes, and because of the changes made to the cold plate in each of these, any change outside of a 1-degree difference will be considered as outside of error.

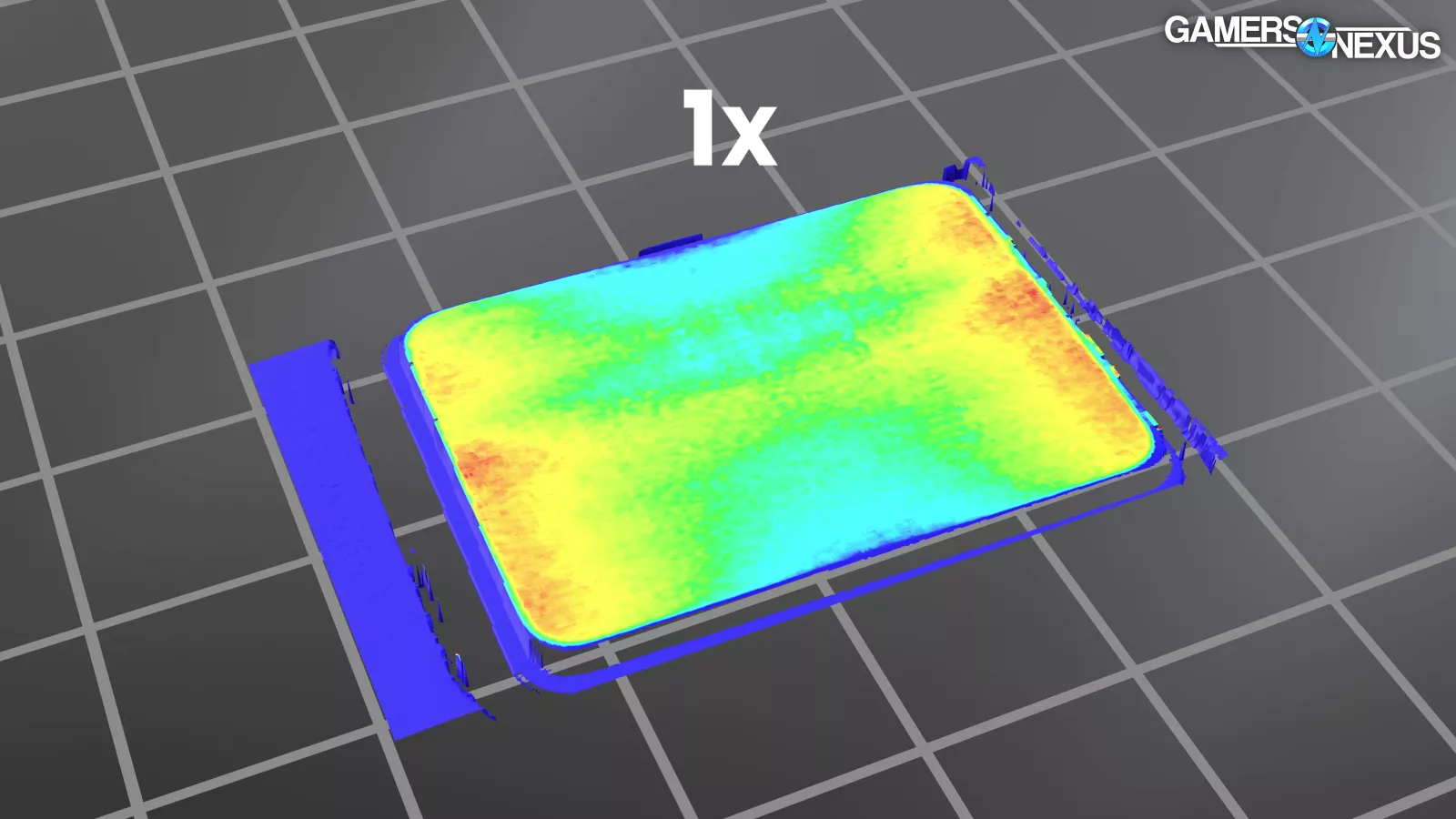

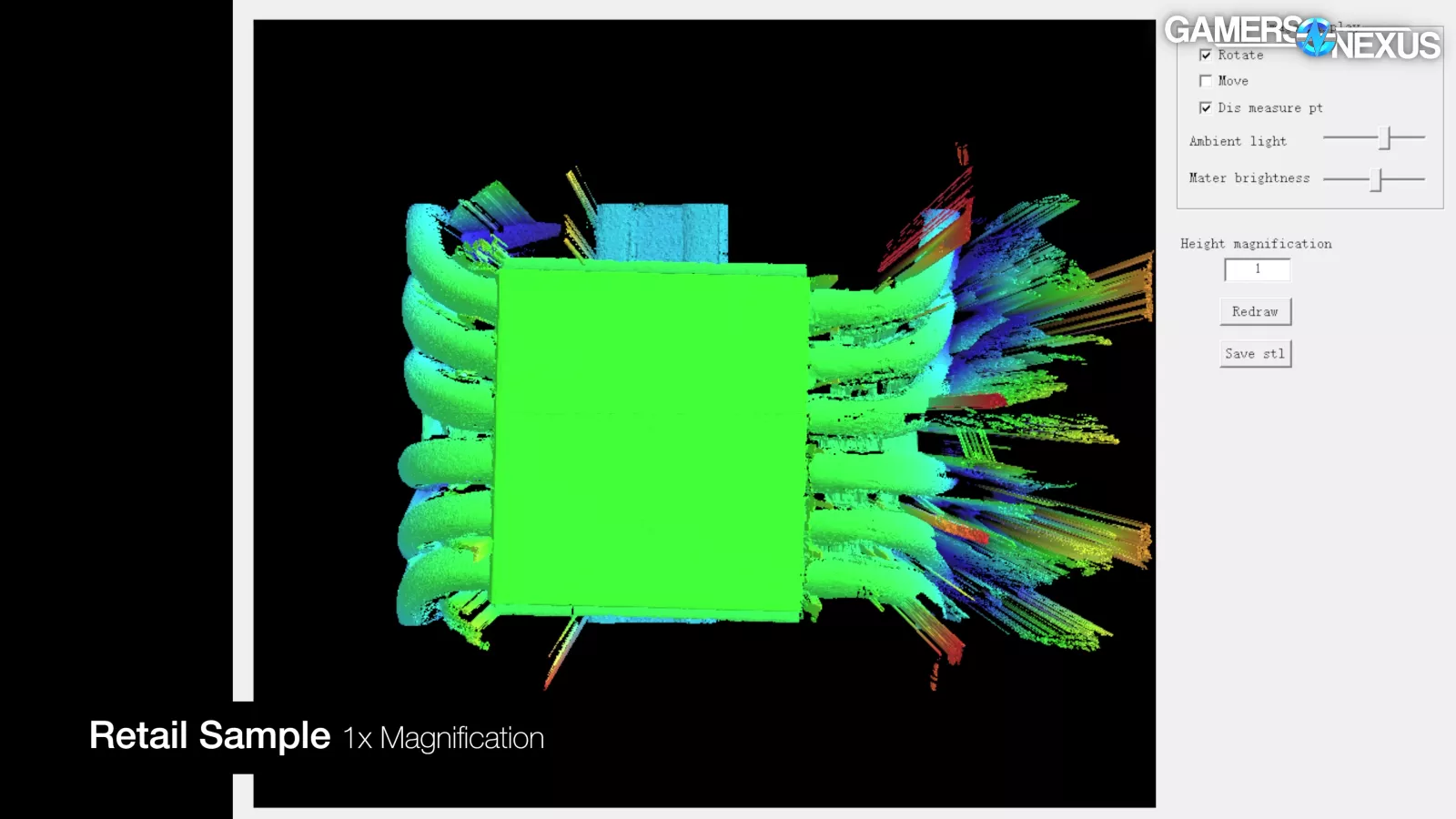

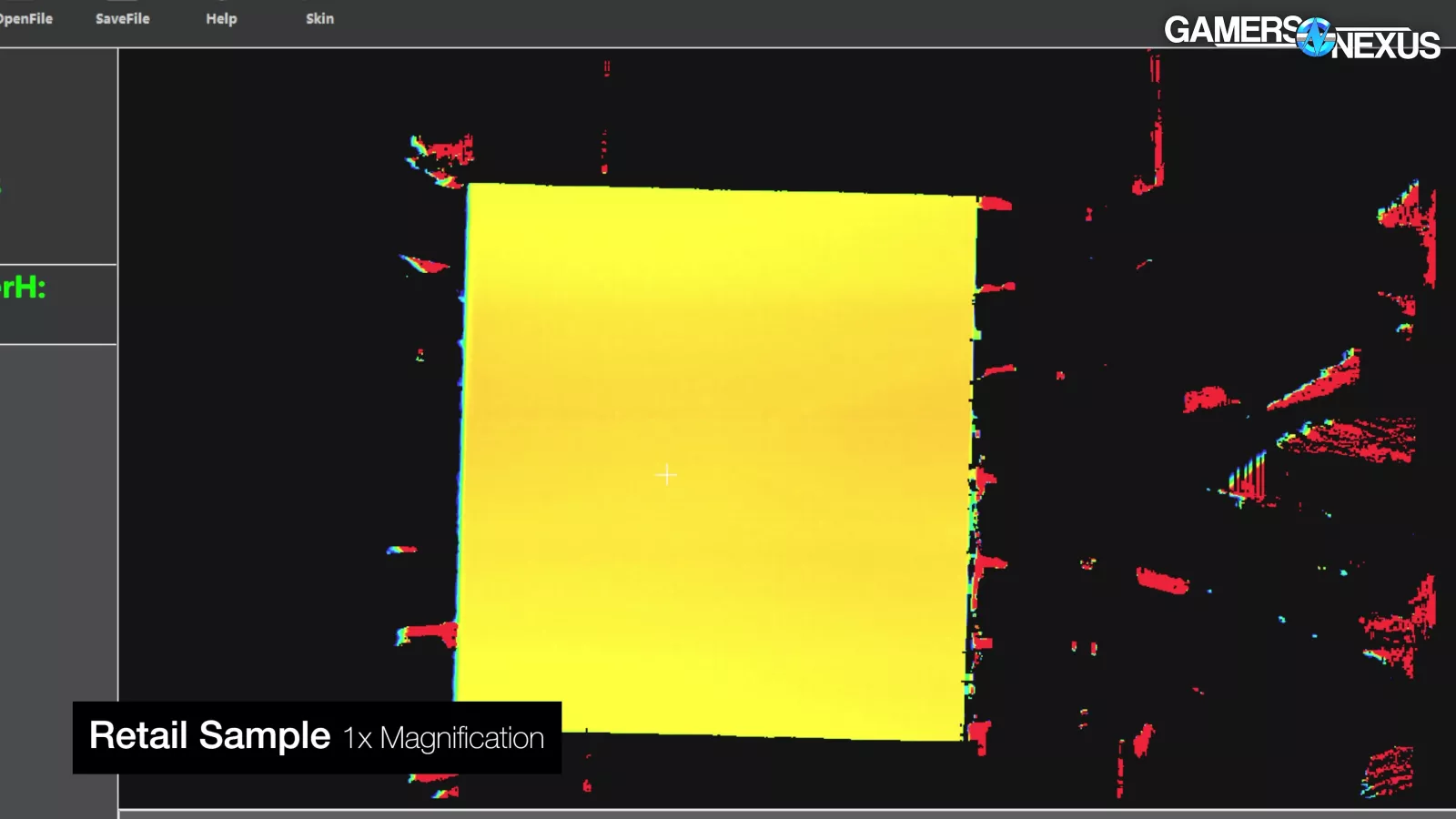

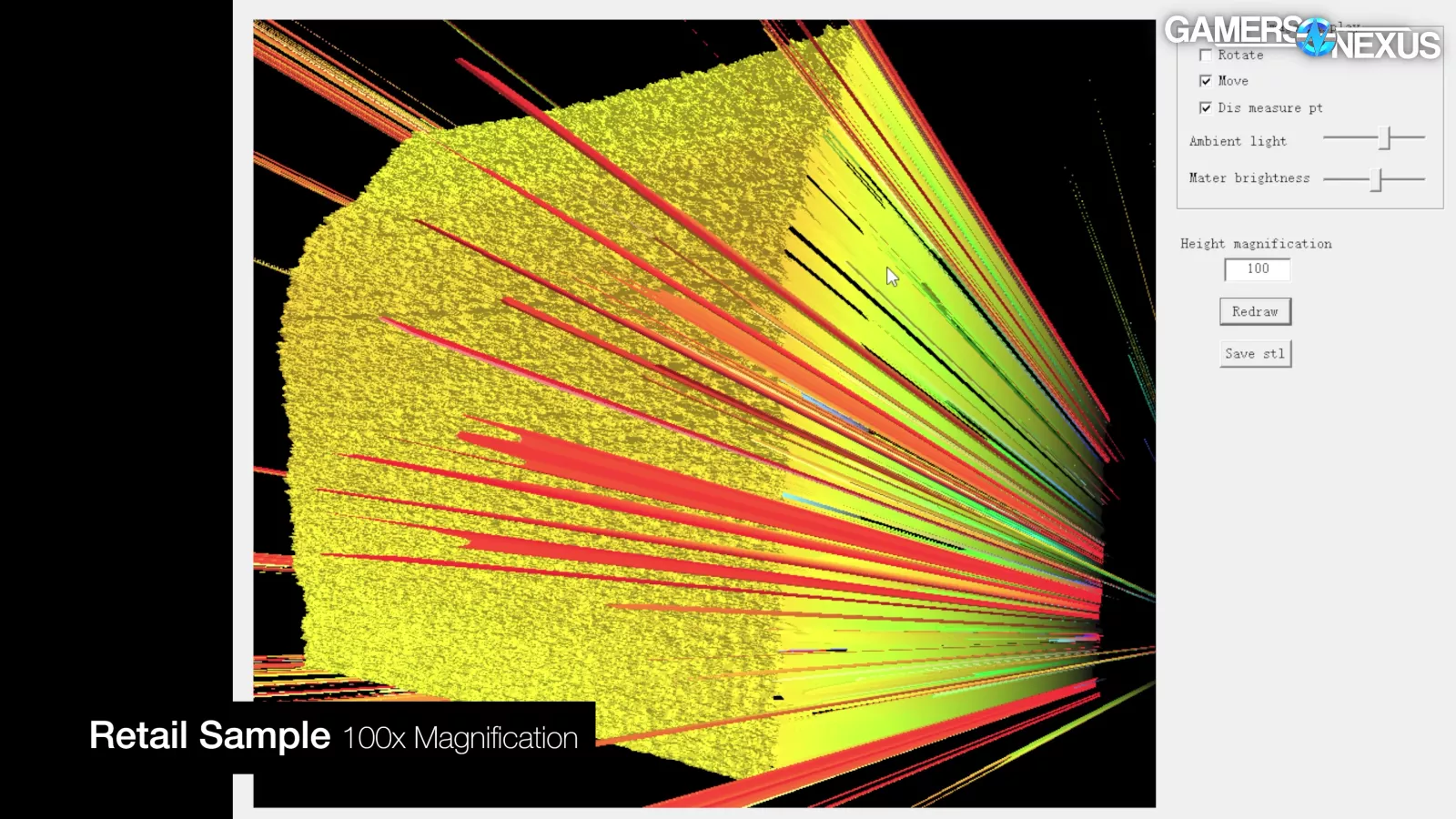

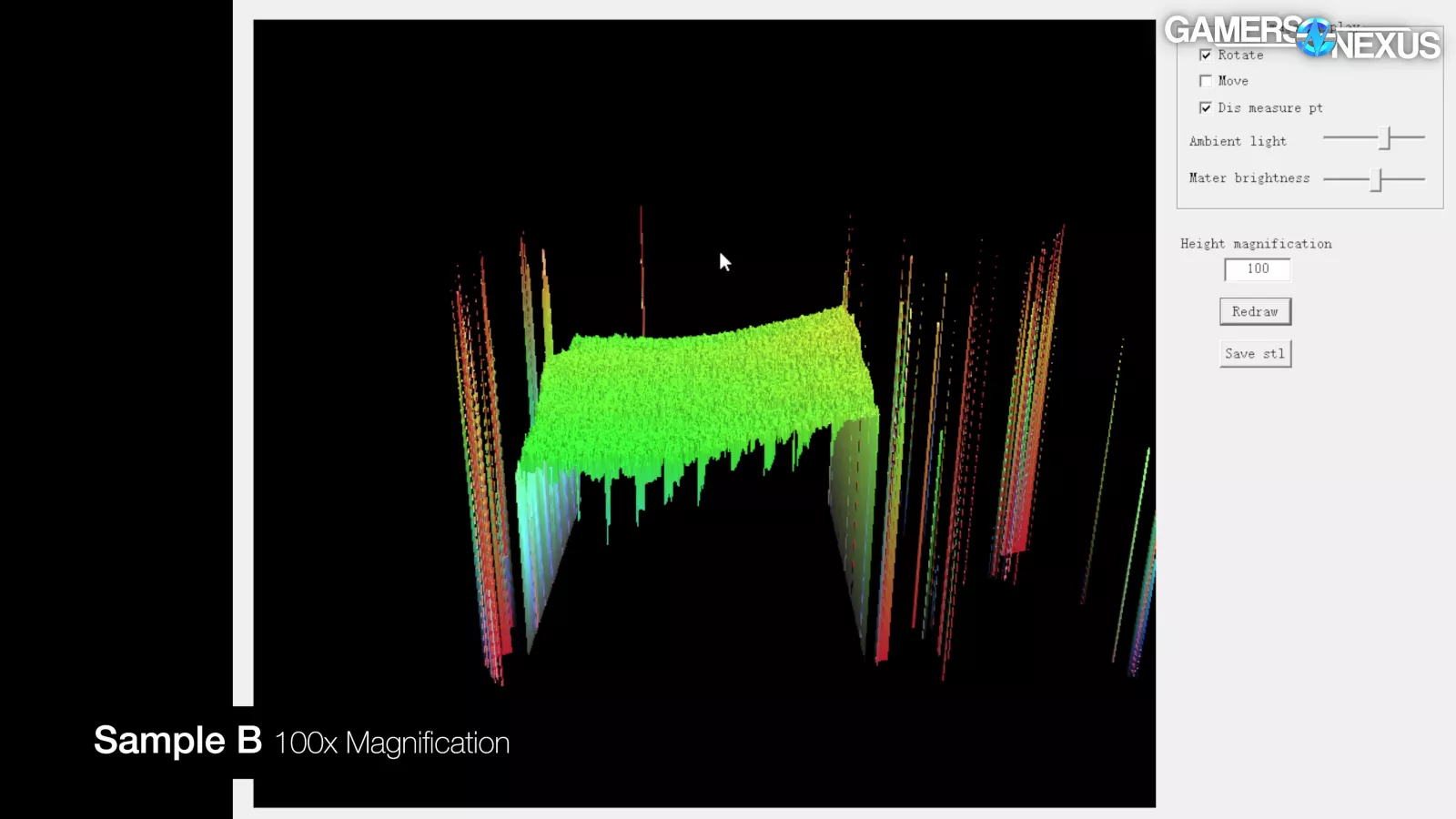

Here’s a scan of a normal Scythe FUMA 3 without modifications. When unmagnified, it just looks kind of flat.

You can see some coloring indicating depth changes at the micron-level, but to really see the curvature, we need to magnify this.

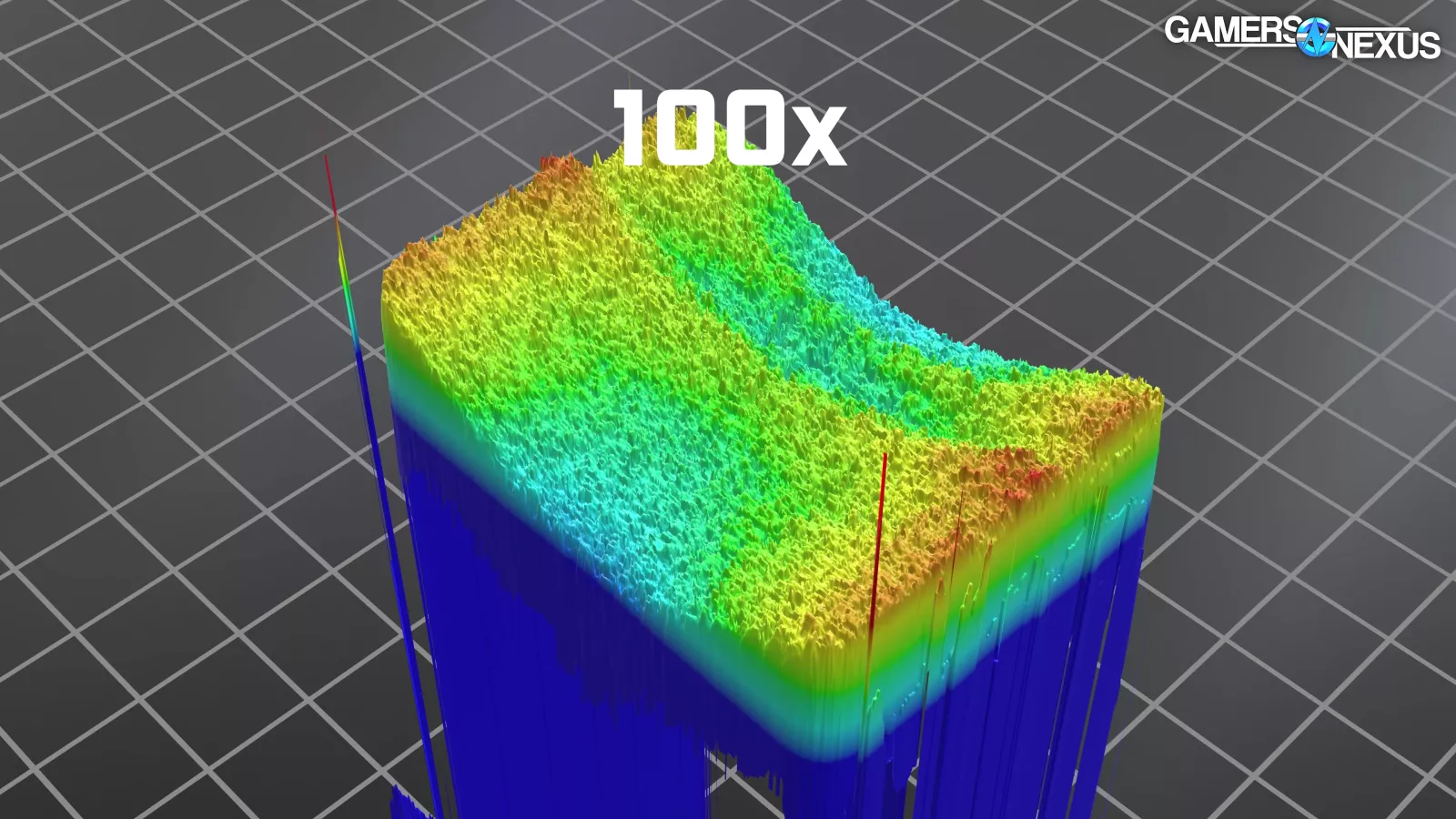

Here’s the same scan boosted at a 100x magnification to reveal details invisible to the human eye. You can see that the cold plate is curving towards the laser. Imagine that the laser is actually the CPU: It is convex and curving centrally towards the CPU IHS; however, as this is magnified at 100x, it’s so slight that it may have no real impact on contact. Pressure distribution and flexing of the plate occur during install, so it’s further possible that this flattens out.

Either way, the normal FUMA 3 (watch our review) is heavily curved as compared to our custom-made AM4 samples.

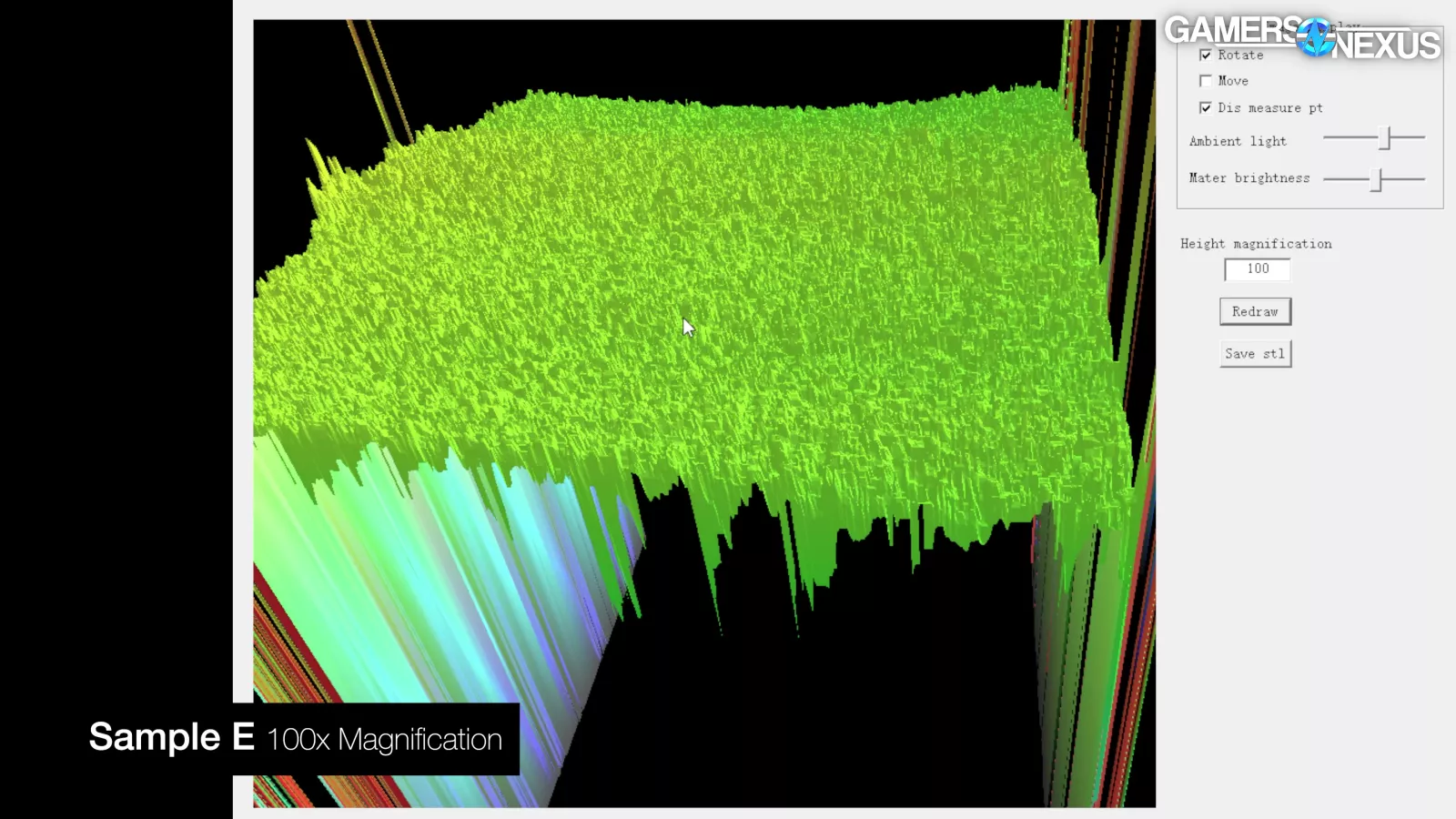

This is Golden Sample E, which you can see is incredibly flat by contrast. It’s impressive how flat they got this plate -- it should work well for AM4.

This is Sample B, which likewise is overall very flat.

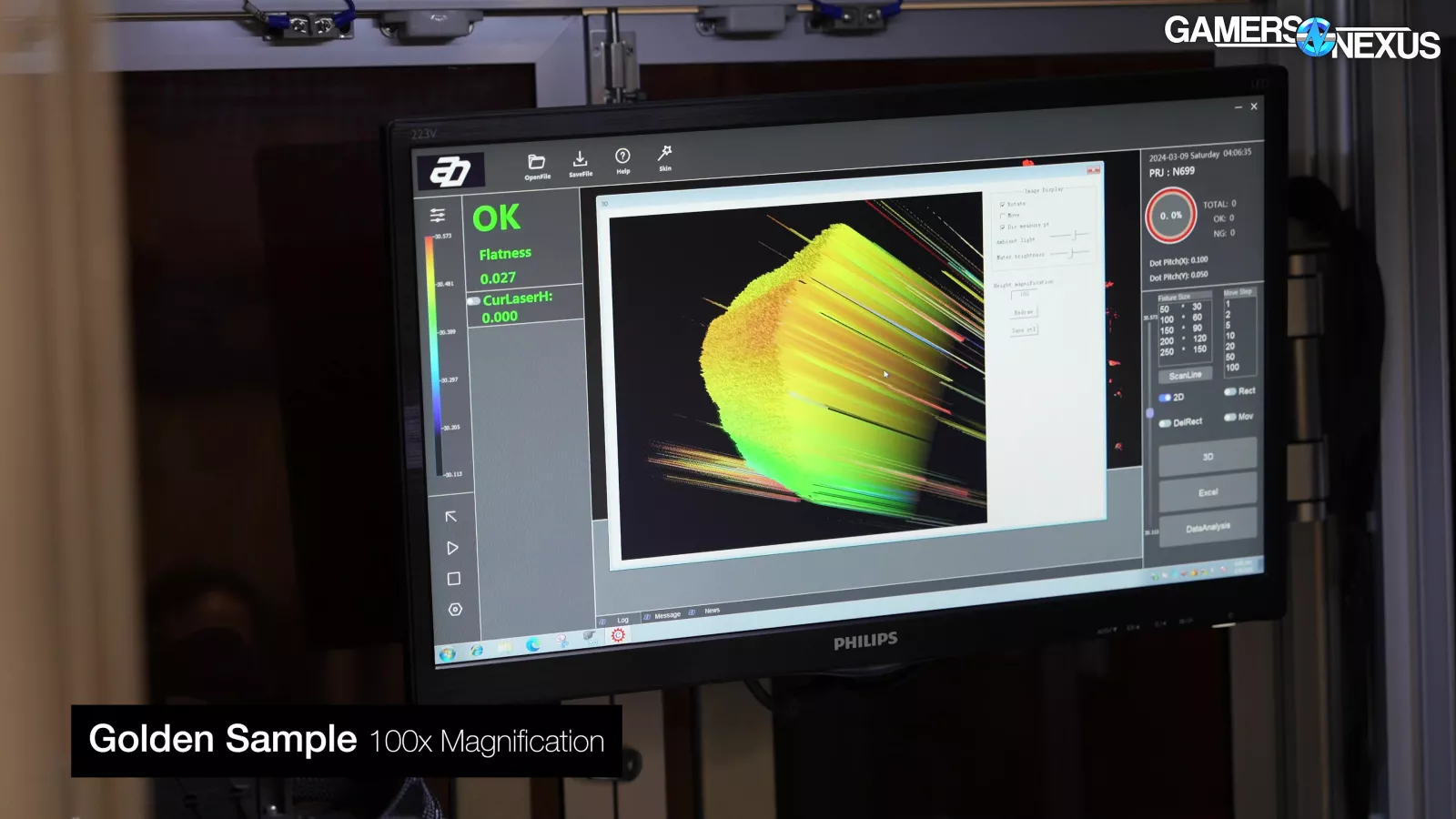

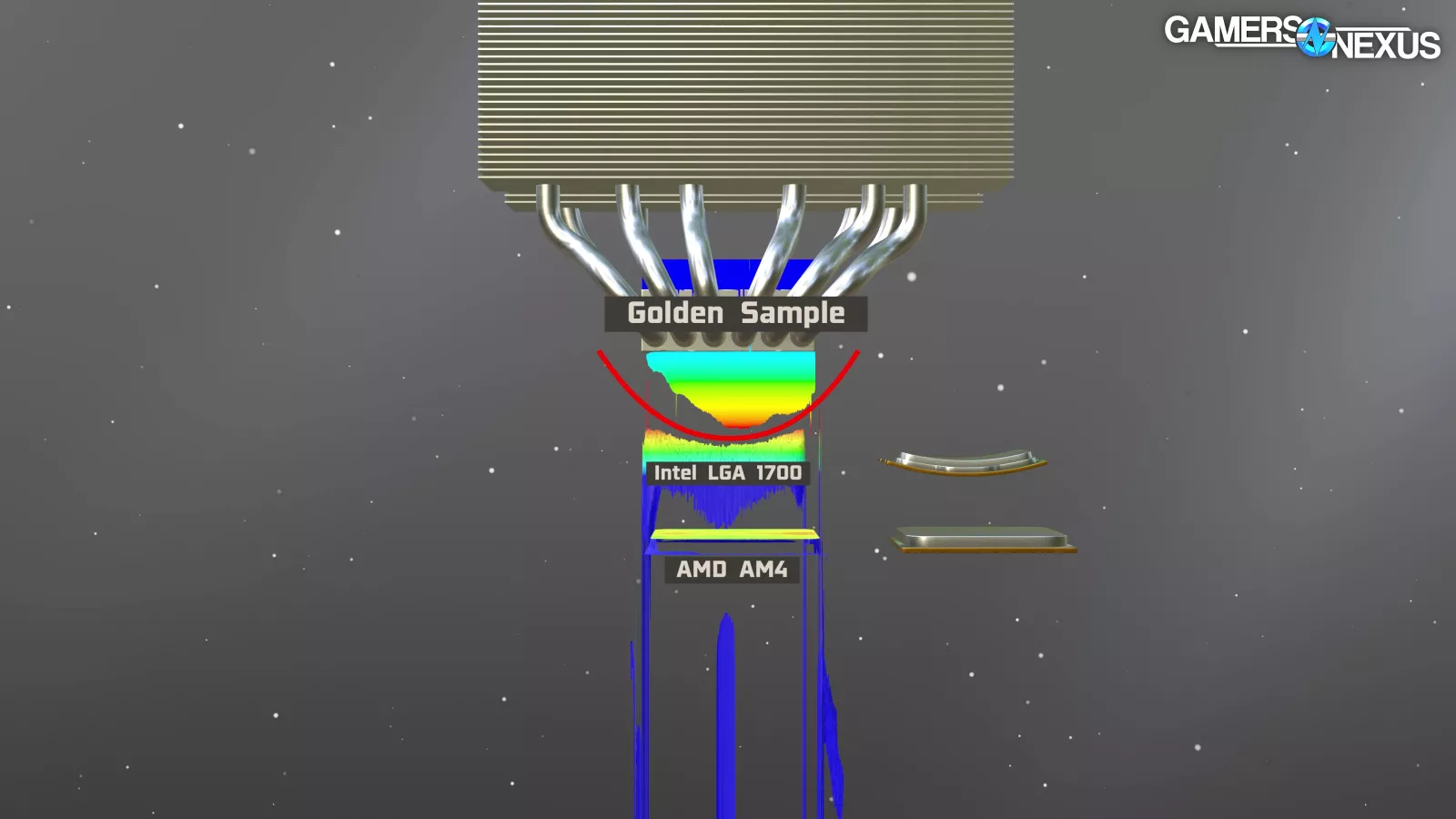

Finally, here’s the actual golden sample unit. This one should be amazing for Intel since the indentation lines-up with the concavity in the IHS when ILM pressure is applied.

The Best Cooler Cold Plate

The scientific process involves disclosing limitations. For this test, they are:

1 - We can’t control the actual heatpipes. It’s possible that there are slight quality variances in heatpipe selection; however, Scythe told us that it regulates its heatpipe supply tightly.

2 - We can control the fans, so we used the same fans at the same speeds and positions for all testing.

Now we need a hypothesis:

Here’s how everything should work:

This Golden Sample cooler should work the best on both AMD AM4 and Intel LGA1700. The reason is because it’s a clever combination of engineering from Scythe in the process of tweaking this cold plate.

When we asked them to curve the cold plate in a convex way to mate with the Intel CPU, we both realized that this curve could be slightly offset to bias it towards the hottest part of the Intel CPU and still land right between most of the Silicon on the AMD CPU, like the IO die. That means that while it mates perfectly with LGA1700, even though it’s not flat, we can apply the most pressure to the chiplet area of the flat AM4 CPU. In theory, this makes it the best possible for each, but would be sub-optimal for AM5 due to the perpendicular intersecting curve.

Sample E and Sample B coolers are flatter, so those should theoretically work better on AM4 than on Intel. Sample E is the best of these two.

The flatness means that Intel, if we exaggerate its curvature, will end up with reduced pressure centrally where the die is.

While AMD will end up with evenly distributed pressure across the IHS but less than the golden sample on the chiplet location.

Thermal Results

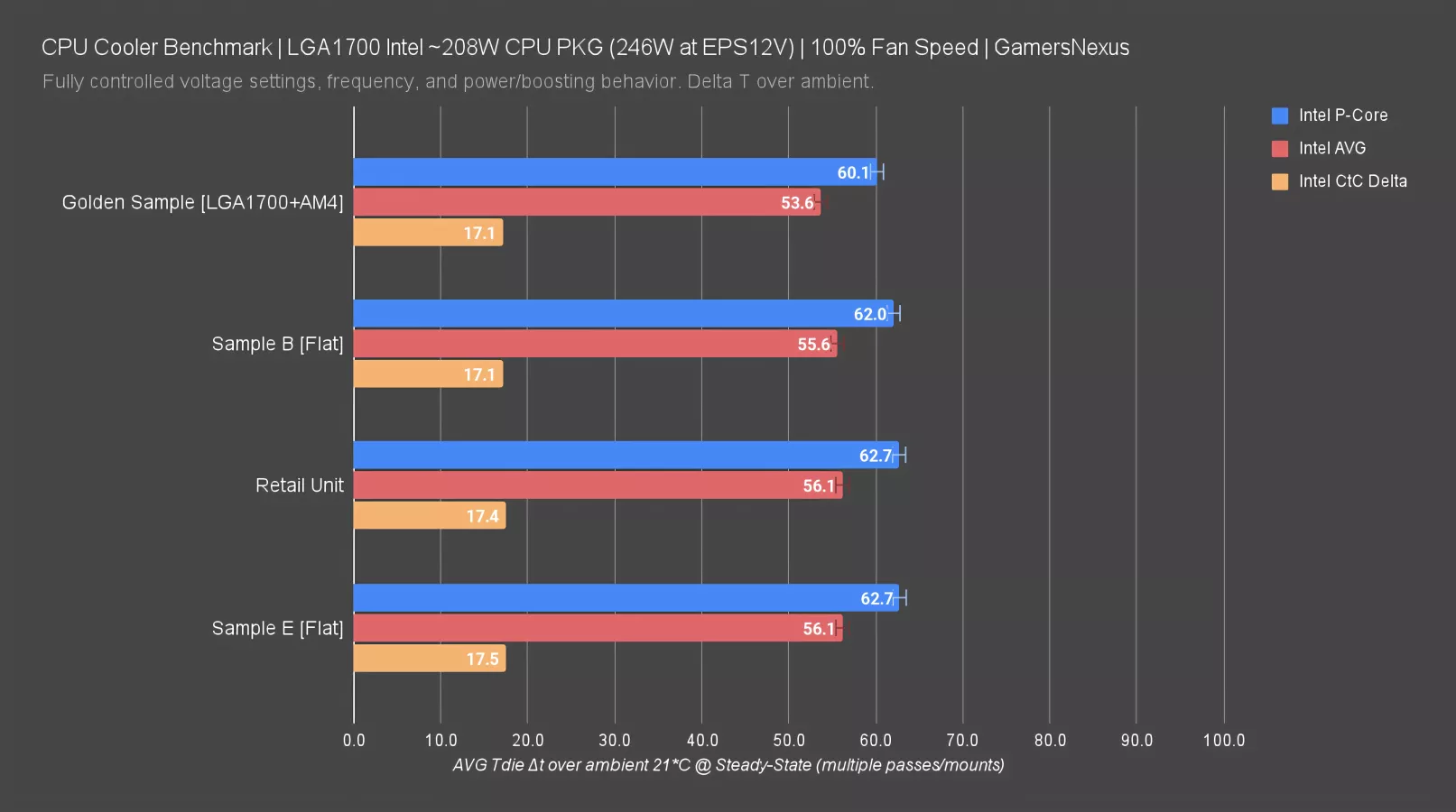

Intel Thermal Results

Here are the Intel thermal results. We theorized that the Golden Sample would do best on Intel, and it does -- by a lot. This is really exciting data, because everything about the way the cold plate is shaped for this one says that it should mate nearly perfectly with that indent on Intel. The end result is almost 3 degrees improved over one of the flattest plates. It’s no wonder Scythe asked us last year if we thought they should sell separate AMD and Intel coolers and no wonder why Noctua has done that sparingly in the past. An extra 2 degrees in the world of air coolers is the difference between the top and the middle of the chart -- that’s huge. The core-to-core delta remained similar, so we’re still limited there by the IHS design, silicone adhesive, and solder there.

Sample B has a very slight curvature to it, and so outperforms Sample E here as a result on Intel.

This is super exciting. Let’s look at the flattest CPU we have: AMD AM4.

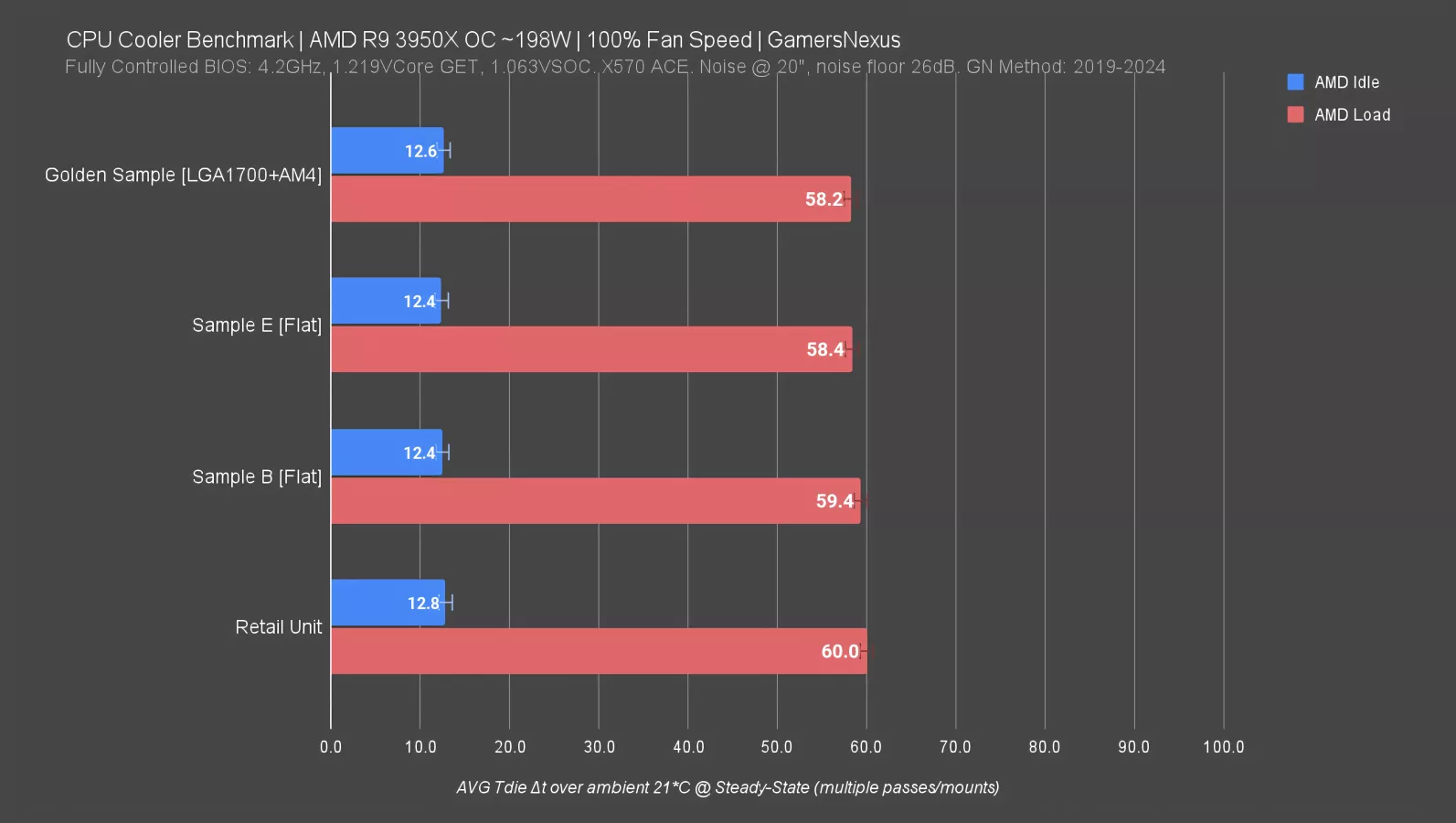

AMD AM4 Thermal Results

The top-to-bottom range is 1.8 degrees. That’s relatively tight together, but definitely outside of our typical 1-degree target for a review. In this instance, with 3 specially tuned samples, our retail unit ends up the warmest. The “golden sample” we requested at Computex ran at 58.2 degrees, so that’s about a 1-degree difference from our typical acceptable margin of error when measured against the retail unit. Some of that is run-to-run variance, but there is a real difference here.

This shows that the Golden Sample we had made still works optimally on AM4 as a result of the highest point of pressure being with the chiplet area, while on Intel, it’s the mating that benefits the design. Sample E is functionally the same: Because of how flat it is, its performance is tied for the best performer on AM4 out of these samples. That’s a big change from the Intel result, where E was the worst performer by 3 degrees. The theory is proving itself to be real. Sample B wasn’t quite as flat and didn’t do as well. Despite being mostly flat, it had an unbiased, slight curvature that wasn’t focused on the chiplets. That worked against it on AM4, but slightly helped it on Intel earlier.

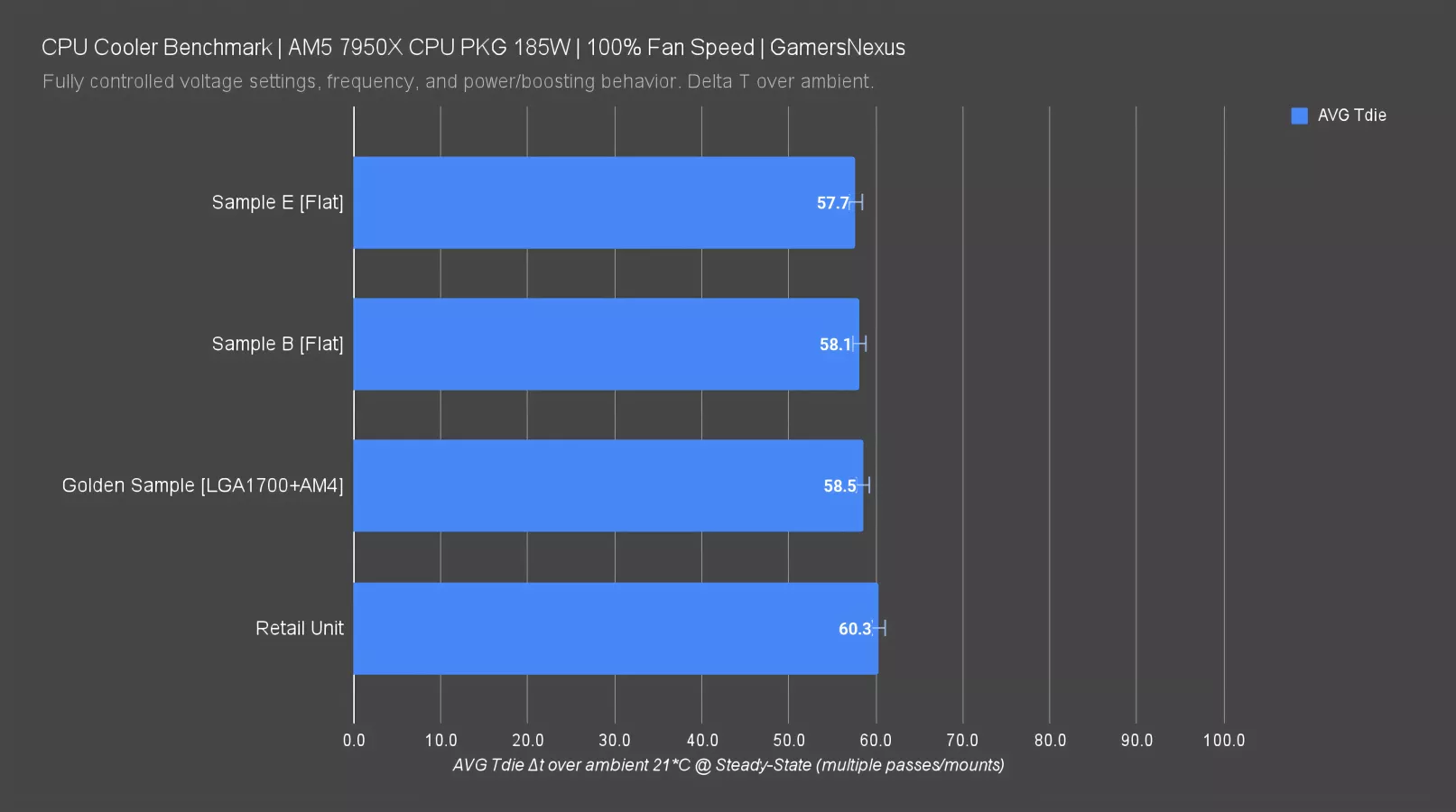

AM5 Thermal Results

We also ran some quick AM5 tests. Using a 7950X set to a clock and VCore that had it pulling 185W. We found Sample E to be the best performer by a lot against retail. Going flatter was better than a curve intersecting the wrong direction. Sample B was also up there, followed by the golden sample. As expected, the golden sample unit lost rank with AM5, otherwise they’d just make it for all platforms.

Retail is unfortunately low for all of these. It does okay since, realistically, we're talking a couple degrees but it appears that there might be a better way to make this. Maybe this is an indication that Scythe should consider adopting one of the experimental designs.

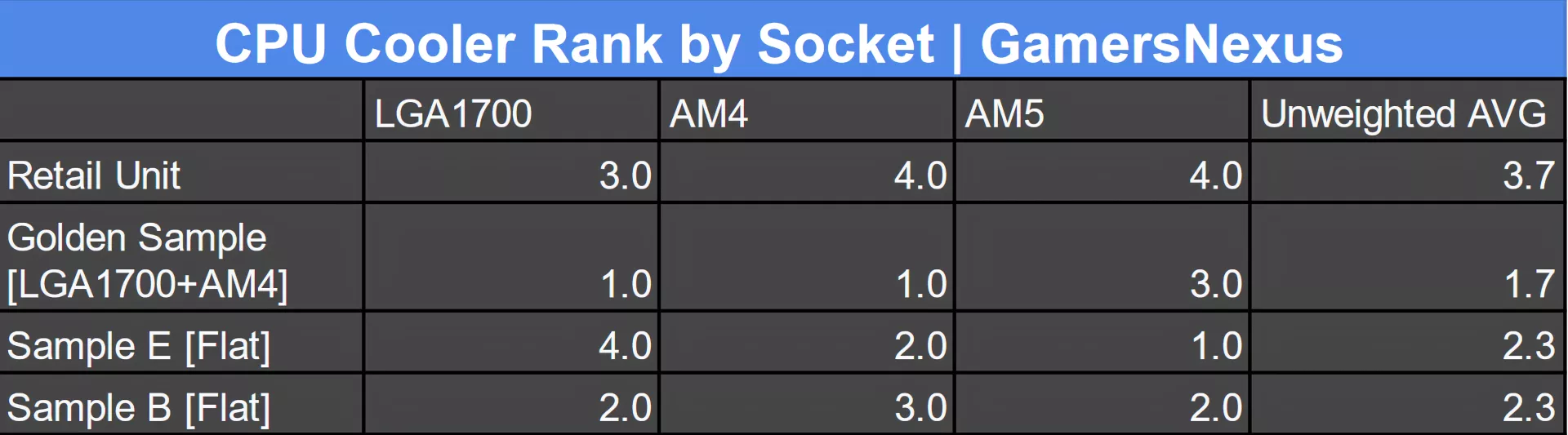

In fact, here’s a quick table to rank them in each test. You can see that the retail unit was the worst in two tests and basically tied for that rank on LGA1700. Now, there’s one downside to the way we did this testing: Since we did ask for finely tuned coolers, it’s possible that we also intersected an area of other sampling bias: For instance, maybe because we bought the retail unit 6 months after the custom one was made, something changed.

Either way, generally speaking, the Golden Sample did best in two places and was only slightly disadvantaged on AM5. This seems to be the best one for the future overall. We’ll regroup with Scythe later at Computex to talk about the findings and see if they apply them to manufacturing.

Pressure Scans

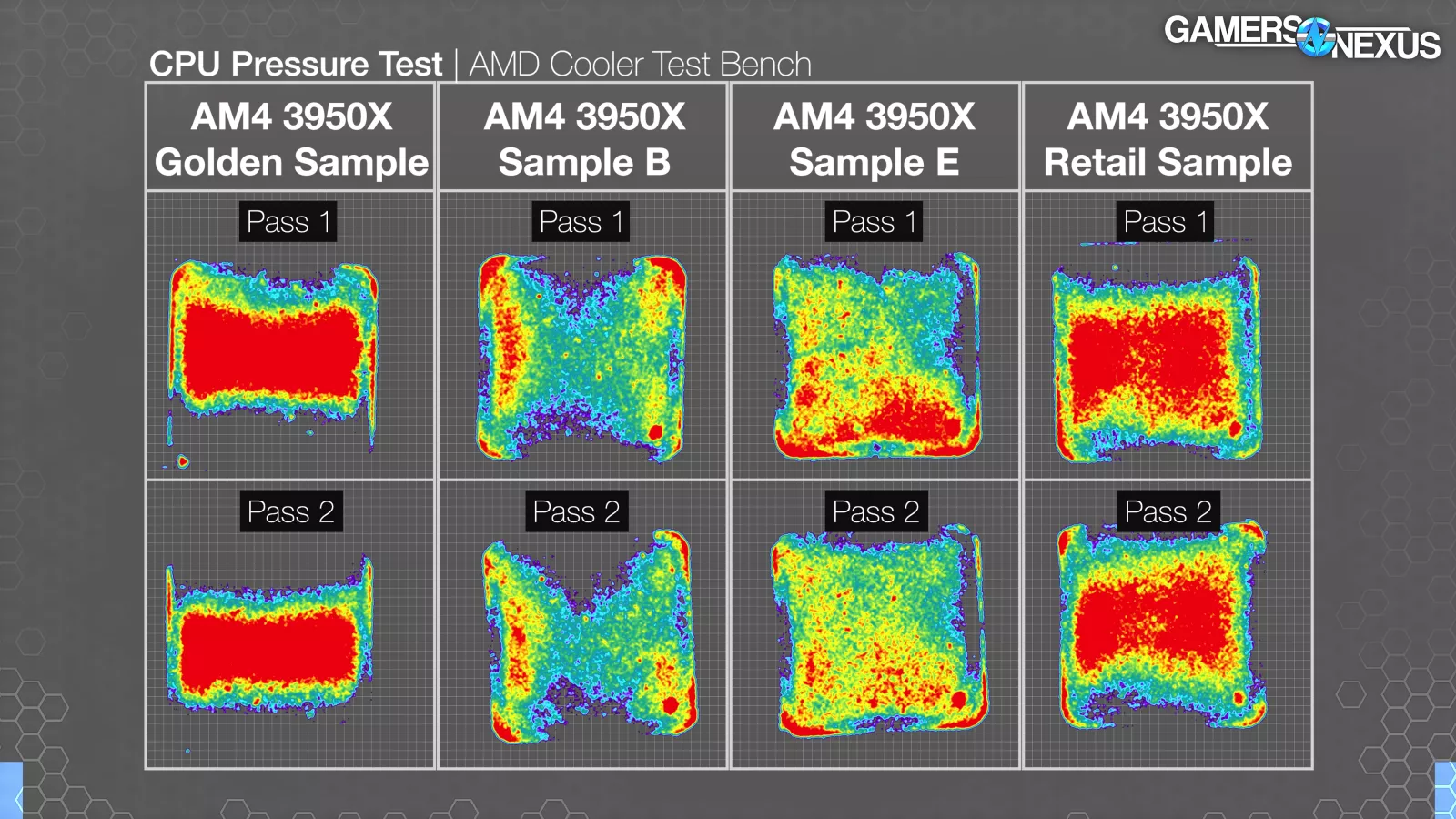

Pressure Scan Results - AM4 3950X

This next section is super cool.

Here’s a pressure scan of an AM4 CPU. The far left scan of the golden sample shows extremely high pressure centrally, right down across the middle of the CPU. If you look at the flatter samples B & E, you can see that we have a wider area of coverage across the entire CPU surface, but reduced pressure centrally. That higher pressure mattered more in our thermal testing for this one. The retail sample has a mixture of higher spread across the IHS and higher pressure centrally, but it has some spotty weak points.

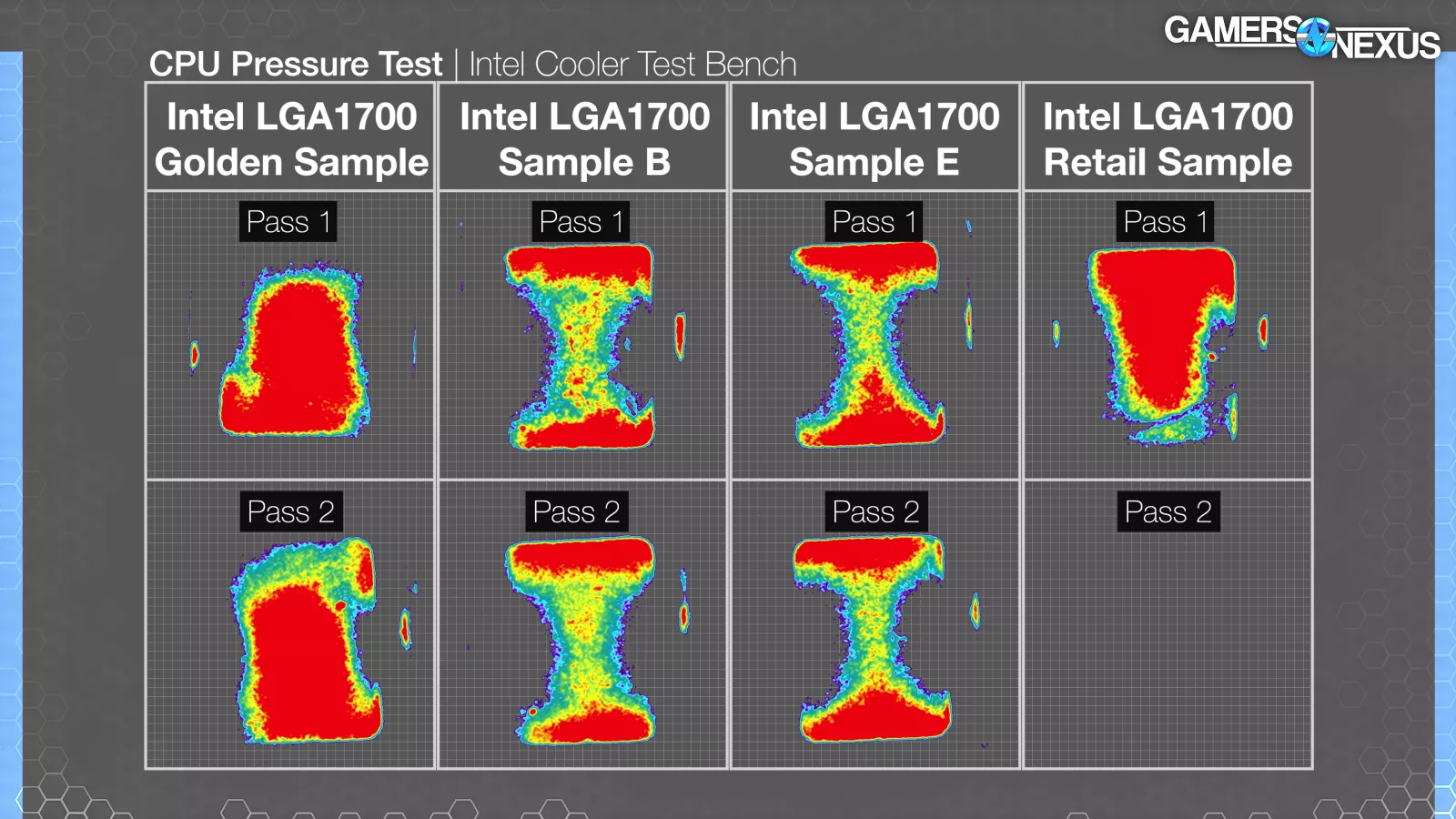

Pressure Scan Results - Intel LGA1700

And here’s the LGA1700 Intel CPU. In this one, you can see the golden sample unit has extremely high pressure centrally. The two flat samples do exactly what we expected: They lose contact along the critical edges of the central channel and have reduced pressure centrally, with only spotty areas of high pressure. This is the most exciting part of the job for us: We get to test a concept and see how it works. Not every aspect worked as we expected, but in this one, it’s exactly what you’d predict from a flat plate on a CPU that gets curved inwards by the ILM. It’s super cool. The retail unit is more similar to the golden sample, just with its less pronounced curve resulting in slightly reduced contact along the top edge.

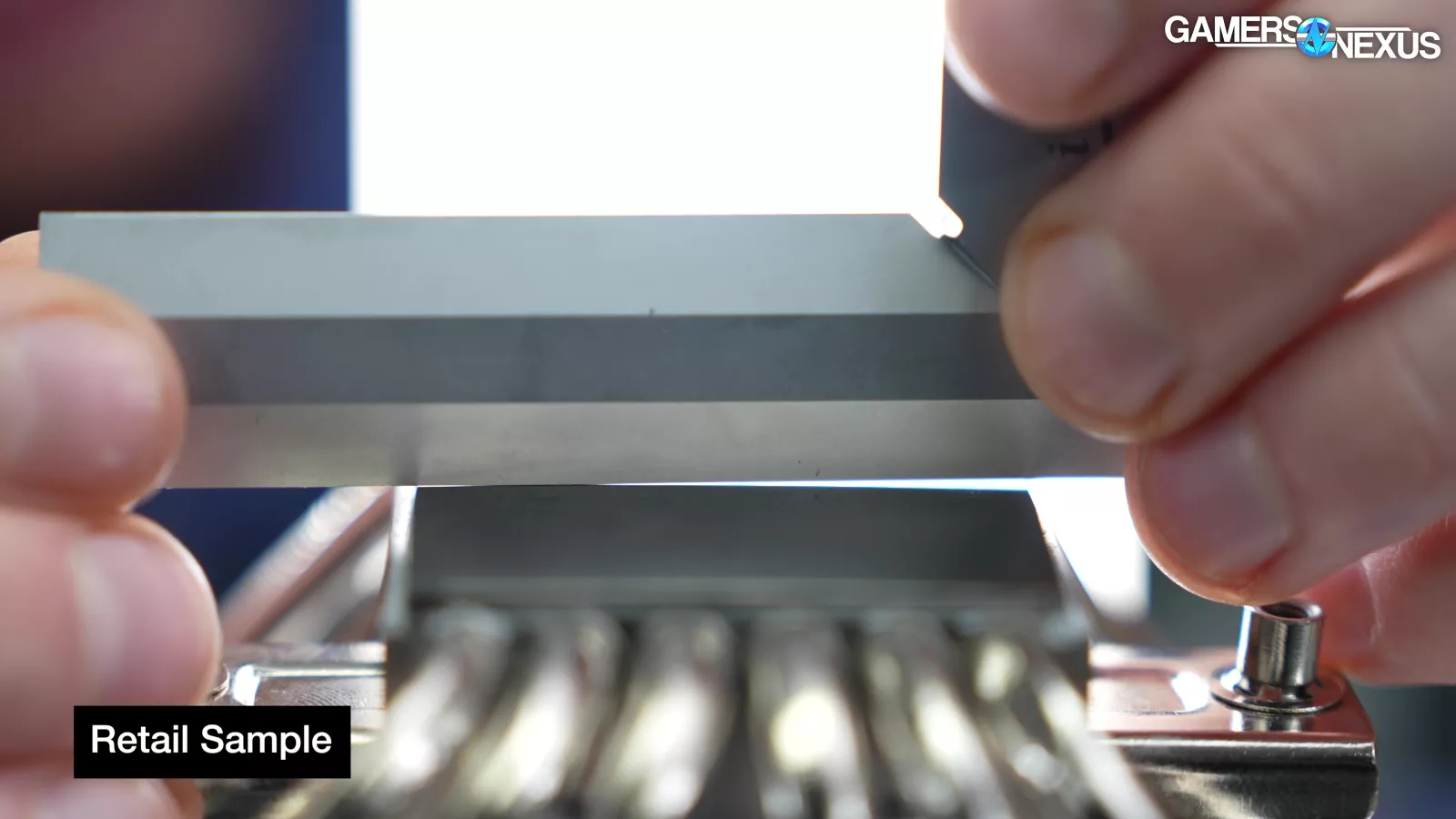

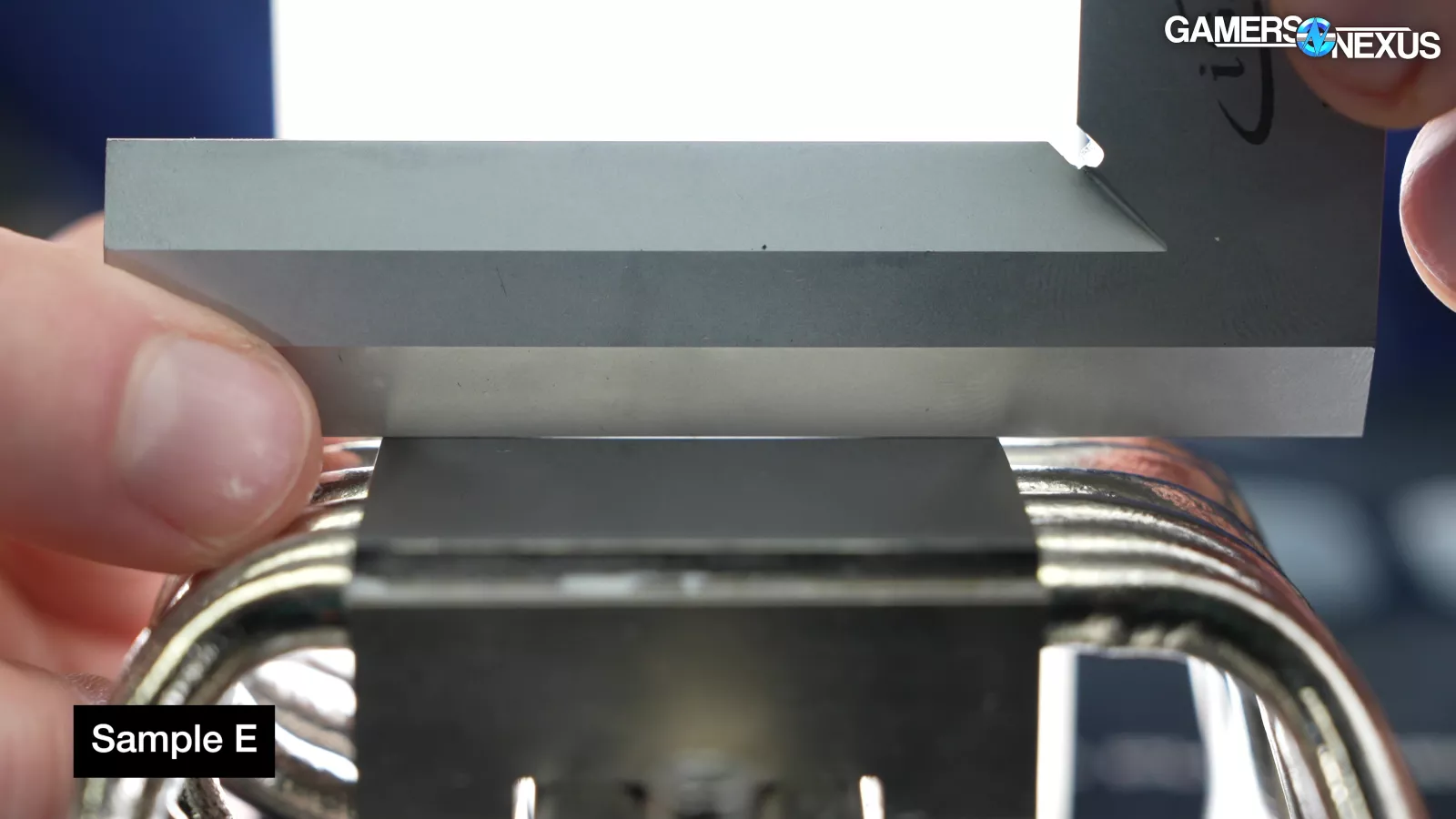

Engineer’s Square

Finally, just for some quick physical visuals with the real product, we took a bunch of footage of the coolers with a high-precision Engineer’s Square and a flashlight. We’ll just show some of that now.

You can see in some situations where the light really cut under the square, illustrating the amount of curvature in the plate. But as we’ve learned now, that curvature can be a powerful tool to improving performance in some CPUs by focusing pressure in key areas or by matching the IHS.

There were others we tested with the Engineer’s Square that blocked most of the light from shining through, and those were generally the custom flat ones that we had made.

Conclusion

Part of our findings didn’t work out how we thought, while others did.

Here’s what didn’t work: The flat plates weren’t as successful as we thought they would be on AMD’s AM4 platform, but in one instance, it tied with the golden sample. Our original hypothesis was that, since AM4 is flat, those plates should perform the best. What we accidentally found was that a slight curvature benefits even AM4 as long as it is biased to intersect the chiplets and maintain high pressure there.

What did work was the golden sample: Having the cold plate shaped to mate with Intel definitely gave that cooler the best Intel performance, and it even worked well on AM4 since it applied the highest pressure to AM4.

From a product perspective: It looks like the perfect cold plate for LGA1700 and AM5 might be opposing each other, but that tuning for LGA1700 can at least get a wide cross-section with AM4. Manufacturers might have a few degrees of performance they can extract from custom tuning, but then they’d have multiple SKUs and would introduce new problems with customer service.

Here’s why we’re doing this: We follow the scientific process, and that means isolating variables. It also means validation. To do all of the validation we do on a single cooler, we spend 40 hours just to test it on a single AM4 platform across 2-3 CPUs and get numbers that anyone can begin to trust. We’ve detailed that process before, but it requires multiple mounts and passes per mount -- each cooler is about a week of testing work for Mike. But that scientific process also means exploring known weaknesses in approach and then trying to solve for them.

We’ve long been open that one of our longest-standing weaknesses in our cooler reviews methodology has been in CPU IHS representation, but due to practical limitations of it costing a lot of money and time, we had to choose a platform we could test and test well, as accurate data on one platform mattered more than inaccurate data across two platforms.

But Intel needs a different shape cold plate for optimal performance, and we’ve finally figured out how to optimize some of our reviews to accommodate both IHS shapes. That’s why the last 3-4 cooler reviews have had Intel and AMD CPUs alike. And now, we get to explore the shape differences and impact on thermals.